Farashin Superalloys

(1) Brazing halaye superalloys za a iya raba uku Categories: nickel tushe, baƙin ƙarfe tushe da cobalt tushe.Suna da kyawawan kaddarorin inji, juriya na iskar shaka da juriya na lalata a yanayin zafi mai yawa.Nickel tushe gami ne mafi yadu amfani a m samar.

Superalloy ya ƙunshi ƙarin Cr, kuma fim ɗin Cr2O3 oxide wanda ke da wahalar cirewa yana samuwa a saman yayin dumama.Nickel base superalloys sun ƙunshi Al da Ti, waɗanda ke da sauƙin oxidize lokacin zafi.Don haka, don hana ko rage oxidation na superalloys yayin dumama da kuma cire fim din oxide shine matsala ta farko a lokacin brazing.Kamar yadda borax ko boric acid a cikin jujjuyawar na iya haifar da lalatar ƙarfen tushe a yanayin zafin brazing, boron ya haɗe bayan abin da ya faru zai iya shiga cikin ƙarfen tushe, wanda ke haifar da kutsewar intergranular.Don simintin simintin nickel tare da babban abun ciki na Al da Ti, ƙimar injin a cikin yanayin zafi ba zai zama ƙasa da 10-2 ~ 10-3pa ba yayin brazing don guje wa iskar shaka a saman gami yayin dumama.

Don ƙarfafa ƙarfin bayani da hazo ƙarfafa tushen gami da nickel, zafin zafin jiki ya kamata ya kasance daidai da zafin zafin jiki na maganin maganin don tabbatar da cikakken rushewar abubuwan gami.Yawan zafin jiki na brazing ya yi ƙasa sosai, kuma abubuwan gami ba za a iya narkar da su gaba ɗaya ba;Idan brazing zafin jiki ya yi yawa, tushen karfe hatsi zai yi girma, kuma kayan kayan ba za a mayar da ko da bayan zafi magani.Tsayayyen zafin bayani na simintin simintin allo yana da girma, wanda gabaɗaya ba zai shafi kaddarorin kayan ba saboda tsananin zafin brazing.

Wasu nickel tushe superalloys, musamman hazo ƙarfafa gami, suna da hali na damuwa fatattaka.Kafin brazing, damuwa da aka samu a cikin aikin dole ne a cire shi gaba ɗaya, kuma ya kamata a rage yawan zafin zafi yayin brazing.

(2) Brazing abu nickel tushe gami za a iya brazed da azurfa tushe, tsarki jan karfe, nickel tushe da kuma aiki solder.Lokacin da zafin aiki na haɗin gwiwa bai yi girma ba, ana iya amfani da kayan tushen azurfa.Akwai nau'ikan siyar da tushen azurfa iri-iri.Don rage damuwa na ciki a lokacin dumama brazing, yana da kyau a zabi mai siyar tare da ƙananan zafin jiki na narkewa.Ana iya amfani da juzu'in Fb101 don brazing tare da ƙarfe mai filler tushe na azurfa.Ana amfani da juzu'in Fb102 don hazo brazing ƙarfafa superalloy tare da mafi girman abun ciki na aluminum, kuma an ƙara 10% ~ 20% sodium silicate ko aluminium flux (kamar fb201).Lokacin da zafin jiki na brazing ya wuce 900 ℃, fb105 za a zaba.

Lokacin yin brazing a cikin sarari ko yanayi mai karewa, ana iya amfani da tagulla zalla azaman ƙarfe mai cike da brazing.Yawan zafin jiki na brazing shine 1100 ~ 1150 ℃, kuma haɗin gwiwa ba zai haifar da fashewar damuwa ba, amma zafin aiki ba zai wuce 400 ℃ ba.

Nickel base brazing filler karfe shine mafi yawan amfani da brazing filler a cikin Superalloys saboda kyakkyawan aikin sa na zafin jiki kuma babu tashin hankali yayin brazing.Babban abubuwan da ake amfani da su a cikin nickel base solder sune Cr, Si, B, da ƙaramin adadin siyar kuma ya ƙunshi Fe, W, da sauransu. na B a cikin gindin karfe kuma ƙara tazarar zafin narkewa.Ƙarfe ce mai jujjuyawar brazing don sarrafa sassa na aiki mai zafin jiki da ruwan injin turbine.Duk da haka, yawan ruwa na W-dauke da solder ya zama mafi muni kuma ratar haɗin gwiwa yana da wuyar sarrafawa.

Ƙarfin filler mai aikin watsawa ba ya ƙunshi Si element kuma yana da kyakkyawan juriya da iskar shaka da juriya vulcanization.Za a iya zaɓar zafin jiki na brazing daga 1150 ℃ zuwa 1218 ℃ bisa ga nau'in solder.Bayan brazing, brazed haɗin gwiwa tare da irin wannan kaddarorin kamar tushe karfe za a iya samu bayan 1066 ℃ yaduwa magani.

(3) Brazing tsarin nickel tushe gami na iya ɗaukar brazing a cikin tanderun yanayi mai karewa, injin ƙura da kuma haɗin lokaci na ruwa na wucin gadi.Kafin yin brazing, dole ne a goge saman kuma a cire oxide ta hanyar goge takarda mai yashi, gogewar motsi, gogewar acetone da tsaftace sinadarai.Lokacin zabar sigogin tsarin brazing, ya kamata a lura cewa zafin zafin jiki bai kamata ya yi girma ba kuma lokacin brazing yakamata ya zama gajere don guje wa halayen sinadarai mai ƙarfi tsakanin juyi da ƙarfe tushe.Don hana tushen karfe daga fashe, sassan da aka sarrafa sanyi za a sami sauƙin damuwa kafin waldawa, kuma dumama walda ya zama daidai kamar yadda zai yiwu.Don haɓakar hazo mai ƙarfi, sassan za su kasance ƙarƙashin ingantaccen magani na farko, sa'an nan kuma a yi brazed a zafin jiki kaɗan sama da jiyya mai ƙarfafa tsufa, kuma a ƙarshe jiyya na tsufa.

1) Brazing a cikin tanderun yanayi mai karewa brazing a cikin tanderun yanayi mai karewa yana buƙatar tsaftar iskar gas mai kariya.Don superalloys tare da w (AL) da w (TI) ƙasa da 0.5%, raɓa zai zama ƙasa da -54 ℃ lokacin amfani da hydrogen ko argon.Lokacin da abun ciki na Al da Ti ya karu, har yanzu saman alloy yana oxidizes lokacin da zafi.Dole ne a dauki matakai masu zuwa;Ƙara ƙaramin ƙarami (kamar fb105) kuma cire fim ɗin oxide tare da juzu'i;0.025 ~ 0.038mm lokacin farin ciki shafi ne plated a saman sassa;Fesa solder a saman kayan da za a yi brazed a gaba;Ƙara ƙaramin adadin iskar gas, kamar boron trifluoride.

2) Vacuum brazing injin brazing ana amfani dashi ko'ina don samun ingantaccen tasirin kariya da ingancin brazing.Dubi tebur 15 don kayan aikin injin nickel tushe superalloy haɗin gwiwa.Don superalloys tare da w (AL) da w (TI) ƙasa da 4%, yana da kyau a sanya wani Layer na 0.01 ~ 0.015mm nickel a saman, kodayake ana iya tabbatar da wetting na solder ba tare da pretreatment na musamman ba.Lokacin da w (AL) da w (TI) suka wuce 4%, kauri na nickel shafi zai zama 0.020.03mm.Matsakaicin bakin ciki ba shi da wani tasiri mai kariya, kuma mai kauri mai kauri zai rage ƙarfin haɗin gwiwa.Hakanan za'a iya sanya sassan da za'a yi walda a cikin akwatin don ɓarke baƙin ƙarfe.Akwatin ya kamata a cika da getter.Misali, Zr yana shakar iskar gas a babban zafin jiki, wanda zai iya samar da gurbi na gida a cikin akwatin, don haka hana iskar shaka daga saman alloy.

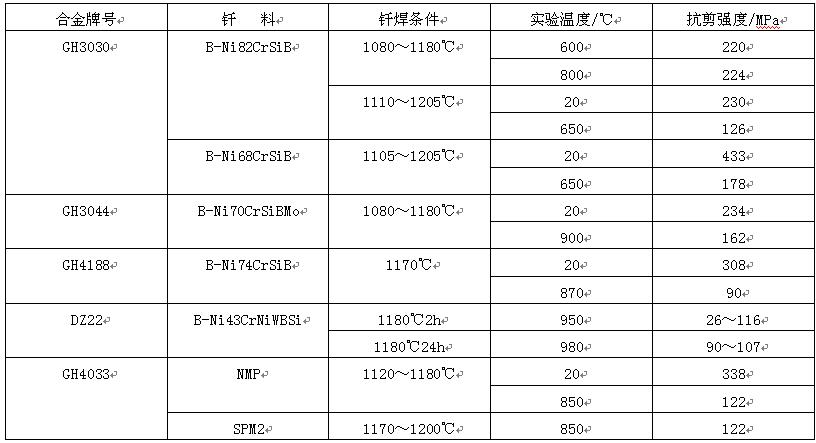

Tebur 15 kayan inji na Vacuum Brazed Joints na al'adar nickel base superalloys

Microstructure da ƙarfin haɗin haɗin gwiwa na Superalloy yana canzawa tare da rata na brazing, da kuma yaduwar jiyya bayan brazing zai ƙara yawan ƙimar da aka yarda da ita na haɗin haɗin gwiwa.Ɗaukar inconel alloy a matsayin misali, matsakaicin rata na haɗin gwiwar Inconel brazed tare da b-ni82crsib zai iya kaiwa 90um bayan maganin yaduwa a 1000 ℃ na 1H;Koyaya, ga gidajen haɗin gwiwa tare da b-ni71crsib, matsakaicin rata shine kusan 50um bayan jiyya na yaduwa a 1000 ℃ don 1H.

3) Haɗin lokacin haɗin ruwa na wucin gadi na wucin gadi na lokaci-lokaci yana amfani da alloy ɗin interlayer (kimanin 2.5 ~ 100um lokacin farin ciki) wanda wurin narkewa ya yi ƙasa da ƙarfen tushe azaman ƙarfe mai filler.A ƙarƙashin ƙaramin matsa lamba (0 ~ 0.007mpa) da zafin jiki mai dacewa (1100 ~ 1250 ℃), kayan interlayer ya fara narkewa kuma yana ɗanɗano karfen tushe.Saboda saurin yaduwar abubuwa, ƙaddamarwar isothermal yana faruwa a haɗin gwiwa don samar da haɗin gwiwa.Wannan hanya tana rage madaidaicin buƙatun tushen ƙarfe na tushe kuma yana rage matsin walda.Babban ma'auni na haɗin lokaci na ruwa na wucin gadi shine matsa lamba, zazzabi, lokacin riƙewa da abun ciki na interlayer.Aiwatar da ƙasa da matsa lamba don kiyaye farfajiyar walda a cikin kyakkyawar hulɗa.Zazzabi zafin jiki da lokaci suna da tasiri mai yawa akan aikin haɗin gwiwa.Idan ana buƙatar haɗin gwiwa don zama mai ƙarfi kamar ƙarfe mai tushe kuma baya shafar aikin ƙarfe mai tushe, sigogin tsarin haɗin haɗin na babban zafin jiki (kamar ≥ 1150 ℃) da dogon lokaci (kamar 8 ~ 24h) karba;Idan an rage ingancin haɗin haɗin haɗin gwiwa ko ƙananan ƙarfe ba zai iya tsayayya da zafi mai zafi ba, za a yi amfani da ƙananan zafin jiki (1100 ~ 1150 ℃) da ɗan gajeren lokaci (1 ~ 8h).Matsakaicin Layer zai ɗauki haɗin haɗin ginin tushe mai haɗawa azaman ainihin abun ciki, kuma ya ƙara abubuwa masu sanyaya daban-daban, kamar B, Si, Mn, Nb, da sauransu. Misali, abun da ke cikin Udimet gami shine ni-15cr-18.5co-4.3 al-3.3ti-5mo, da abun da ke ciki na tsaka-tsakin Layer don haɗin lokaci na ruwa mai wucewa shine b-ni62.5cr15co15mo5b2.5.Duk waɗannan abubuwan zasu iya rage zafin narkewar Ni Cr ko Ni Cr Co gami zuwa mafi ƙasƙanci, amma tasirin B shine mafi bayyane.Bugu da kari, babban yaduwa kudi na B iya sauri homogenize da interlayer gami da tushe karfe.

Lokacin aikawa: Juni-13-2022