Ma'anar da manufar quenching

Ana dumama karfen zuwa yanayin zafi sama da mahimmin batu Ac3 (karfe na hypoeutectoid) ko Ac1 (karfe na hypereutectoid), ana ajiye shi na wani lokaci don sanya shi gabaɗaya ko kuma a ɗan inganta shi, sannan kuma a sanyaya shi cikin sauri fiye da saurin kashewa. Tsarin maganin zafi wanda ke canza supercooled austenite zuwa martensite ko ƙananan bainite ana kiransa quenching.

Manufar quenching shine a canza austenite mai sanyi zuwa martensite ko bainite don samun tsarin martensite ko ƙananan bainite, wanda aka haɗa shi da zafin jiki a yanayin zafi daban-daban don inganta ƙarfin, taurin, da juriya na karfe. Wearability, ƙarfin gajiya da taurin kai, da sauransu, don saduwa da buƙatun amfani daban-daban na sassa da kayan aikin injiniya daban-daban. Hakanan ana iya amfani da Quenching don saduwa da abubuwan musamman na zahiri da sinadarai na wasu ƙarfe na musamman kamar feromagnetism da juriya na lalata.

Lokacin da aka sanyaya sassa na ƙarfe a cikin matsakaiciyar kashewa tare da canje-canje a yanayin jiki, tsarin sanyaya gabaɗaya ya kasu zuwa matakai uku masu zuwa: matakin fim ɗin tururi, matakin tafasa, da kuma matakin convection.

Hardenability na karfe

Hardenability da taurin alamu ne na aiki guda biyu waɗanda ke nuna ƙarfin ƙarfe don jurewa. Hakanan mahimman tushe ne don zaɓin abu da amfani.

1. Ma'anar hardenability da hardenability

Hardenability shine ƙarfin ƙarfe don cimma mafi girman taurin da zai iya samu lokacin da aka kashe da taurare a ƙarƙashin kyakkyawan yanayi. Babban abin da ke ƙayyade ƙarfin ƙarfe shine abun ciki na carbon na karfe. Don zama madaidaici, abun cikin carbon ne da aka narkar da shi a cikin austenite yayin kashewa da dumama. Mafi girman abun ciki na carbon, mafi girman ƙarfin ƙarfin ƙarfe. . Abubuwan da aka haɗa a cikin ƙarfe suna da tasiri kaɗan akan ƙarfin ƙarfin, amma suna da tasiri mai mahimmanci akan ƙarfin ƙarfe.

Hardenability yana nufin halayen da ke ƙayyade zurfin taurin da rarraba taurin ƙarfe a ƙarƙashin ƙayyadaddun yanayi. Wato, ikon samun zurfin zurfin Layer lokacin da aka kashe karfe. Ƙarfe ce ta asali. Hardenability a zahiri yana nuna sauƙin da austenite ke canzawa zuwa martensite lokacin da aka kashe ƙarfe. Yana da alaƙa da alaƙa da kwanciyar hankali na supercooled austenite na ƙarfe, ko zuwa ƙimar sanyaya mai mahimmanci na ƙarfe.

Har ila yau, ya kamata a nuna cewa taurin karfe dole ne a bambanta daga tasiri mai zurfi na sassa na karfe a ƙarƙashin ƙayyadaddun yanayi na quenching. Ƙarƙashin ƙarfin ƙarfe wani abu ne na asali na karfe da kansa. Ya dogara ne kawai akan abubuwan ciki na kansa kuma ba shi da alaƙa da abubuwan waje. Ƙarfin ƙarfin ƙarfi mai tasiri na ƙarfe ba kawai ya dogara da ƙarfin ƙarfe ba, amma kuma ya dogara da kayan da aka yi amfani da su. Yana da alaƙa da abubuwan waje kamar matsakaicin sanyaya da girman aiki. Misali, a karkashin yanayi na ingantawa, taurin karfe iri daya iri daya ne, amma ingantacciyar zurfin datsewar ruwa ya fi girma fiye da na kashe mai, kuma kananan sassa sun yi kasa da kashe mai. Ingantacciyar hardening zurfin manyan sassa yana da girma. Wannan ba za a iya cewa kashe ruwa yana da ƙarfi fiye da kashe mai. Ba za a iya cewa ƙananan sassa suna da ƙarfin ƙarfi fiye da manyan sassa. Ana iya ganin cewa don kimanta ƙarfin ƙarfin ƙarfe, dole ne a kawar da tasirin abubuwan waje kamar siffar aiki, girman, matsakaicin sanyaya, da dai sauransu.

Bugu da kari, tun da hardening da hardening ra'ayoyi ne daban-daban guda biyu, karfe tare da babban taurin bayan quenching ba lallai ba ne ya sami babban ƙarfin ƙarfi; kuma karfe tare da ƙananan taurin yana iya samun ƙarfin ƙarfi.

2. Abubuwan da ke shafar ƙarfin ƙarfi

Hardenability na karfe ya dogara da kwanciyar hankali na austenite. Duk wani abu da zai iya inganta kwanciyar hankali na supercooled austenite, matsar da C zuwa dama, kuma ta haka ne rage yawan sanyaya mai mahimmanci zai iya inganta ƙarfin ƙarfe mai girma. Zaman lafiyar austenite ya dogara ne akan nau'in sinadarai, girman hatsi da daidaiton abun da ke ciki, waɗanda ke da alaƙa da sinadarai na ƙarfe da yanayin dumama.

3.Hanyar auna ƙarfin ƙarfi

Akwai hanyoyi da yawa don auna ƙarfin ƙarfin ƙarfe, waɗanda aka fi amfani da su sune hanyar auna diamita mai mahimmanci da kuma hanyar gwaji ta ƙarshe.

(1) Hanyar aunawa mai mahimmanci

Bayan an kashe karfe a cikin wani matsakaici, matsakaicin diamita lokacin da ainihin ya sami duk martensite ko 50% tsarin martensite ana kiransa diamita mai mahimmanci, wanda Dc ke wakilta. Hanyar ma'auni mai mahimmanci shine don yin jerin sandunan zagaye tare da diamita daban-daban, kuma bayan quenching, auna taurin U curve da aka rarraba tare da diamita akan kowane ɓangaren samfurin, kuma sami sanda tare da tsarin semi-martensite a tsakiya. Diamita na sandar zagaye Wato mahimmancin diamita. Mafi girman diamita mai mahimmanci, mafi girman ƙarfin ƙarfin ƙarfe.

(2) Ƙarshen hanyar gwajin kashewa

Hanyar gwaji ta ƙare-ƙushe tana amfani da madaidaicin ƙima mai ƙarewa (Ф25mm × 100mm). Bayan an inganta shi, ana fesa ruwa a gefe ɗaya na samfurin akan kayan aiki na musamman don kwantar da shi. Bayan sanyaya, ana auna taurin tare da jagorar axis - daga ƙarshen ruwan sanyi. Hanyar gwaji don lanƙwan dangantaka ta nisa. Hanyar gwaji ta ƙarshe tana ɗaya daga cikin hanyoyin da za a tantance ƙarfin ƙarfe. Amfaninsa shine aiki mai sauƙi da kewayon aikace-aikace.

4.Quenching danniya, nakasawa da fatattaka

(1) Ciki danniya na workpiece a lokacin quenching

Lokacin da workpiece yana da sauri sanyaya a cikin quenching matsakaici, tun da workpiece yana da wani size da kuma thermal conductivity coefficient shi ma wani darajar, wani zafin jiki gradient zai faru tare da ciki sashe na workpiece a lokacin sanyaya tsari. Yanayin zafin jiki yana da ƙasa, babban zafin jiki yana da girma, kuma saman ƙasa da yanayin zafi suna da girma. Akwai bambancin yanayin zafi. A lokacin aikin sanyaya kayan aiki, akwai kuma abubuwa biyu na zahiri: ɗayan shine haɓakawar thermal, yayin da zafin jiki ya faɗi, tsayin layin aikin aikin zai ragu; ɗayan shine canjin austenite zuwa martensite lokacin da zafin jiki ya faɗi zuwa madaidaicin canjin martensite. , wanda zai ƙara ƙayyadaddun ƙarar. Saboda bambance-bambancen zafin jiki a lokacin aikin sanyaya, adadin haɓakar thermal zai bambanta a sassa daban-daban tare da sashin giciye na aikin, kuma za a haifar da damuwa na ciki a sassa daban-daban na aikin. Saboda kasancewar bambance-bambancen zafin jiki a cikin kayan aikin, ana iya samun sassan da zafin jiki ya ragu da sauri fiye da inda martensite ke faruwa. Canji, ƙarar yana faɗaɗa, kuma sassan da ke da zafin jiki har yanzu suna da girma fiye da ma'ana kuma har yanzu suna cikin yanayin austenite. Wadannan sassa daban-daban kuma za su haifar da damuwa na ciki saboda bambance-bambance a cikin takamaiman canje-canjen girma. Don haka, ana iya haifar da nau'ikan damuwa na ciki guda biyu yayin aikin kashewa da sanyaya: ɗaya shine damuwa na thermal; ɗayan shine damuwa na nama.

Dangane da halaye na lokaci na damuwa na ciki, ana iya raba shi zuwa damuwa nan take da saura. Danniya na ciki wanda aikin aikin ya haifar a wani lokaci yayin aikin sanyaya ana kiransa damuwa nan take; bayan da workpiece aka sanyaya, da danniya da ya rage a cikin workpiece ake kira saura danniya.

Damuwa na thermal yana nufin damuwa da ke haifar da rashin daidaituwar haɓakar thermal (ko ƙanƙantar sanyi) saboda bambance-bambancen zafin jiki a sassa daban-daban na aikin lokacin da aka yi zafi (ko sanyaya).

Yanzu ɗauki ƙaƙƙarfan Silinda a matsayin misali don kwatanta samuwar da canza ƙa'idodin damuwa na ciki yayin aikin sanyaya. An tattauna matsalolin axial kawai a nan. A farkon sanyaya, saboda yanayin yana yin sanyi da sauri, yanayin zafi ya ragu, kuma yana raguwa da yawa, yayin da ainihin sanyi yake, yanayin zafi yana da girma, kuma raguwa yana da ƙananan. A sakamakon haka, saman da ciki sun kame juna, yana haifar da damuwa a kan saman, yayin da ainihin ke ƙarƙashin matsin lamba. damuwa. Yayin da sanyi ya ci gaba, bambancin zafin jiki tsakanin ciki da waje yana ƙaruwa, kuma damuwa na ciki yana ƙaruwa daidai. Lokacin da damuwa ya ƙaru don wuce ƙarfin amfanin gona a wannan zafin jiki, nakasar filastik yana faruwa. Tunda kaurin zuciya ya fi na saman sama, zuciya ta kan fara kulla axially da farko. Sakamakon nakasar filastik, damuwa na ciki baya karuwa. Bayan sanyaya zuwa wani lokaci, raguwar zafin jiki zai ragu sannu a hankali, kuma raguwar ta zai ragu a hankali. A wannan lokacin, jigon yana ci gaba da raguwa, don haka damuwa da damuwa a saman da kuma matsa lamba akan ainihin zai ragu a hankali har sai sun ɓace. Duk da haka, yayin da ake ci gaba da sanyaya, zafi na saman yana raguwa da ƙasa, kuma adadin raguwa ya zama ƙasa da ƙasa, ko ma yana daina raguwa. Tun da yawan zafin jiki a cikin ainihin yana da girma, zai ci gaba da raguwa, kuma a ƙarshe za a kafa danniya mai matsa lamba a saman kayan aikin, yayin da ainihin zai sami damuwa mai ƙarfi. Duk da haka, tun da zafin jiki ya yi ƙasa, nakasar filastik ba ta da sauƙi don faruwa, don haka wannan damuwa zai karu yayin da ake ci gaba da sanyaya. Yana ci gaba da karuwa kuma a ƙarshe ya kasance a cikin kayan aiki azaman ragowar damuwa.

Ana iya ganin cewa zafin zafin jiki yayin aikin sanyaya da farko yana haifar da shimfidar shimfidar shimfidar wuri da kuma matsawa a ciki, sauran damuwan da ya rage shi ne za a matsa saman Layer da kuma cibiya.

Don taƙaitawa, damuwa na thermal da aka haifar a lokacin sanyi mai sanyi yana faruwa ne ta hanyar bambance-bambancen zafin jiki na giciye yayin aikin sanyaya. Mafi girman adadin sanyaya kuma mafi girman bambance-bambancen zafin jiki na giciye, mafi girman ƙarfin zafi da aka haifar. A karkashin wannan yanayin sanyaya matsakaici, mafi girma da dumama zafin jiki na workpiece, da girma girma, da karami da thermal watsin da karfe, da girma da zazzabi bambanci a cikin workpiece, kuma mafi girma thermal danniya. Idan workpiece aka sanyaya unevenly a high zafin jiki, shi za a gurbata da nakasu. Idan danniya na gaggawar da aka haifar yayin aikin sanyaya na kayan aikin ya fi ƙarfin juzu'in kayan aiki, fashewar fasa za ta faru.

Matsakaicin canjin lokaci yana nufin damuwa da ke haifar da lokaci daban-daban na canjin lokaci a sassa daban-daban na aikin aikin yayin aikin jiyya na zafi, wanda kuma aka sani da damuwa na nama.

A lokacin quenching da sauri sanyaya, lokacin da saman Layer aka sanyaya zuwa Ms batu, martensitic canji yana faruwa da kuma haifar da girma fadada. Duk da haka, saboda toshewar tushen da bai riga ya sami canji ba, saman saman yana haifar da damuwa, yayin da ainihin yana da damuwa. Lokacin da damuwa ya yi girma sosai, zai haifar da nakasawa. Lokacin da aka sanyaya ainihin abin zuwa wurin Ms, kuma za ta sami canji mai ƙarfi da faɗaɗa cikin girma. Duk da haka, saboda ƙayyadaddun yanayin da aka canza tare da ƙananan filastik da ƙarfin ƙarfi, damuwa na ƙarshe na ƙarshe zai kasance a cikin yanayin tashin hankali, kuma ainihin zai kasance ƙarƙashin matsin lamba. Ana iya ganin cewa canji da yanayin ƙarshe na damuwa na canjin lokaci sun saba da damuwa na thermal. Haka kuma, tun lokacin da damuwa canjin lokaci ke faruwa a ƙananan yanayin zafi tare da ƙarancin filastik, nakasawa yana da wahala a wannan lokacin, don haka damuwa canjin lokaci yana iya haifar da fashewar kayan aikin.

Akwai dalilai da yawa waɗanda ke shafar girman damuwa na canjin lokaci. Da sauri da sanyaya adadin karfe a cikin kewayon canji na martensite, girman girman yanki na karfe, mafi munin yanayin zafi na karfe, mafi girman ƙayyadaddun ƙarar martensite, mafi girman damuwa canjin lokaci. Ya fi girma. Bugu da ƙari, damuwa na canji na lokaci kuma yana da alaƙa da abun da ke ciki na karfe da ƙarfin ƙarfin karfe. Alal misali, babban carbon high gami karfe yana ƙara ƙayyadaddun ƙarar martensite saboda babban abun ciki na carbon, wanda yakamata ya ƙara ƙarfin canjin lokaci na ƙarfe. Koyaya, yayin da abun cikin carbon ke ƙaruwa, ma'anar Ms yana raguwa, kuma akwai adadi mai yawa na austenite da aka riƙe bayan quenching. Girman girmansa yana raguwa kuma ragowar damuwa yana da ƙasa.

(2) nakasar da workpiece a lokacin quenching

A lokacin quenching, akwai nau'i biyu na nakasawa a cikin workpiece: daya shi ne canji a cikin geometric siffar workpiece, wanda aka bayyana a matsayin canje-canje a cikin girma da kuma siffar, sau da yawa ake kira warping nakasawa, wanda aka lalacewa ta hanyar quenching danniya; ɗayan shine nakasar ƙara. , wanda ke bayyana kanta a matsayin faɗaɗa madaidaici ko ƙaddamar da ƙarar kayan aiki, wanda ya haifar da canji a cikin ƙayyadaddun ƙarar yayin canjin lokaci.

Nakasar warping kuma ya haɗa da nakasar siffa da nakasar karkatarwa. Twist nakasawa yawanci lalacewa ta hanyar rashin dacewa na workpiece a cikin tanderun lokacin dumama, ko rashin siffatawa magani bayan nakasar gyara kafin quenching, ko m sanyaya na daban-daban sassa na workpiece lokacin da workpiece aka sanyaya. Ana iya nazarin wannan nakasar da kuma warware shi don takamaiman yanayi. Abubuwan da ke gaba suna magana ne akan nakasar ƙara da nakasar siffa.

1) Dalilan kashe nakasu da canza dokokinta

Nakasar ƙarar da ta haifar da canjin tsarin Tsarin tsarin aikin aikin kafin kashewa gabaɗaya pearlite ne, wato, tsarin gauraye na ferrite da siminti, kuma bayan quenching shine tsarin martensitic. Ƙididdigar ƙayyadaddun ƙayyadaddun ƙayyadaddun waɗannan kyallen takarda za su haifar da canje-canjen girma kafin da kuma bayan quenching, haifar da nakasawa. Duk da haka, wannan nakasawa kawai yana haifar da aikin aikin don fadadawa da kwangila daidai gwargwado, don haka baya canza siffar aikin.

Bugu da ƙari, mafi yawan martensite a cikin tsarin bayan maganin zafi, ko mafi girma da abun ciki na carbon a cikin martensite, mafi girman girman girman girmansa, kuma mafi girman adadin da aka riƙe austenite, ƙananan ƙarar ƙarar. Sabili da haka, ana iya sarrafa canjin ƙarar ta hanyar sarrafa abun ciki na dangi na martensite da sauran martensite yayin maganin zafi. Idan an sarrafa shi da kyau, ƙarar ba zai faɗaɗa ko raguwa ba.

Nakasar siffar da ta haifar da damuwa na thermal nakasar da ke haifar da matsananciyar zafi yana faruwa a wurare masu zafi inda ƙarfin ƙarfin ƙarfe na sassa ya ragu, filastik yana da girma, saman ya yi sanyi da sauri, kuma bambancin zafin jiki tsakanin ciki da waje na workpiece shine mafi girma. A wannan lokacin, damuwa na thermal na nan take shine damuwa na jujjuyawar sama da matsi na matsi. Tun da ainihin zafin jiki yana da girma a wannan lokacin, ƙarfin yawan amfanin ƙasa ya fi ƙasa da ƙasa, don haka yana bayyana a matsayin nakasawa a ƙarƙashin aikin damuwa na matsawa da yawa, wato, cube yana da siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar zuwa girman girman girman girman girman girman girman girman da girman girman girman. Iri-iri. Sakamakon shine mafi girma yana raguwa, yayin da ƙarami ya faɗaɗa. Misali, dogon Silinda yana gajarta a tsayin shugabanci kuma yana faɗaɗa cikin diamita.

Nakasar siffa da ta haifar da damuwa na nama Nakasar da damuwa na nama ke haifarwa kuma yana faruwa a farkon lokacin lokacin da damuwa na nama ya fi girma. A wannan lokacin, bambancin zafin jiki na giciye yana da girma, babban zafin jiki ya fi girma, har yanzu yana cikin yanayin austenite, filastik yana da kyau, kuma ƙarfin yawan amfanin ƙasa yana da ƙasa. Matsi na nama na nan take shine damuwa matsa lamba na sama da matsi na jijiya. Sabili da haka, nakasar yana bayyana a matsayin elongation na core a ƙarƙashin aikin damuwa mai yawa. Sakamakon shi ne cewa a karkashin aikin danniya na nama, mafi girma gefen workpiece elongates, yayin da karami gefen shortens. Misali, nakasar da ke haifar da damuwa na nama a cikin dogon Silinda shine elongation a tsayi da raguwa a diamita.

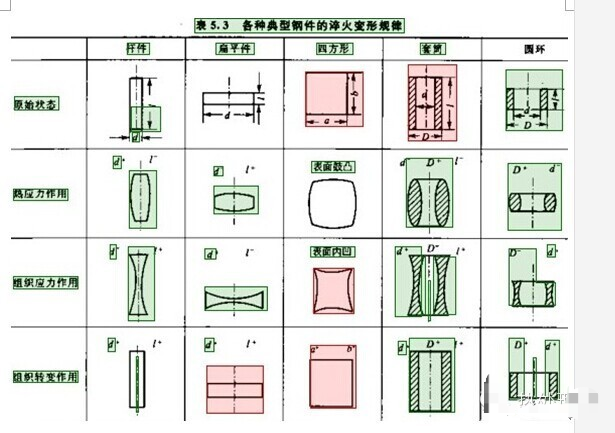

Tebur 5.3 yana nuna ƙa'idodin ɓarna na ɓarna na sassa daban-daban na ƙarfe na yau da kullun.

2) Abubuwan da ke shafar nakasawa

Abubuwan da ke shafar nakasar kashewa sune galibi sinadarai na ƙarfe, tsarin asali, lissafin sassan sassa da tsarin kula da zafi.

3) Yanke tsagewa

Cracks a sassa yafi faruwa a ƙarshen mataki na quenching da sanyaya, wato, bayan an kammala canjin martensitic ko kuma bayan an gama sanyaya, gazawar raguwa yana faruwa saboda damuwa mai ƙarfi a cikin sassan ya wuce ƙarfin karyewar karfe. Cracks yawanci suna karkata zuwa ga matsakaicin nakasar juzu'i, don haka nau'ikan fashe daban-daban a sassa sun dogara ne akan yanayin rarraba damuwa.

Nau'o'in fashe fashe na yau da kullun: Tsage-tsalle na tsayi (axial) ana haifar da su ne musamman lokacin da damuwa mai ƙarfi na tangential ya wuce ƙarfin karyewar kayan; Ana samun faɗuwar ɓarna lokacin da babban damuwa mai ƙarfi na axial da aka kafa akan saman ɓangaren ɓangaren ya wuce ƙarfin karyewar kayan. Karas; an kafa tsagewar hanyar sadarwa a ƙarƙashin aikin damuwa mai girma biyu a saman; fashe fashe yana faruwa a cikin wani sirara mai tauri mai bakin ciki, wanda zai iya faruwa lokacin da danniya ya canza sosai kuma yawan damuwa mai yawa yana aiki a cikin radial. Irin fasa.

Tsawon tsayi kuma ana kiransa axial cracks. Kararrawa suna faruwa a matsakaicin matsakaicin danniya kusa da saman sashin, kuma suna da takamaiman zurfin zuwa tsakiyar. Hanyar tsaga gabaɗaya tana layi ɗaya da axis, amma alƙawarin kuma na iya canzawa lokacin da damuwa a cikin ɓangaren ko lokacin da akwai lahani na ciki.

Bayan aikin aikin ya ƙare gaba ɗaya, tsage-tsafe na tsaye yana yiwuwa ya faru. Wannan yana da alaƙa da babban damuwa mai ƙarfi na tangential akan saman kayan aikin da aka kashe. Yayin da abun ciki na carbon na karfe ya karu, dabi'ar haifar da tsagewar tsayi yana karuwa. Low carbon karfe yana da ƙananan ƙayyadaddun ƙarar martensite da ƙarfin zafi mai ƙarfi. Akwai babban matsi da ya rage a saman, don haka ba shi da sauƙi a kashe shi. Yayin da abun ciki na carbon ya karu, damuwa na matsa lamba yana raguwa kuma tsarin tsarin yana ƙaruwa. A lokaci guda, matsananciyar damuwa tana motsawa zuwa saman saman. Saboda haka, babban carbon karfe ne yiwuwa ga a tsaye quenching fasa a lokacin da overheated.

Girman sassan kai tsaye yana rinjayar girma da rarraba damuwa na saura, kuma yanayin kashewar sa shima ya bambanta. Tsawon tsayin tsayi kuma ana samun sauƙi ta hanyar kashewa a cikin kewayon girman ɓangaren ɓangaren haɗari. Bugu da kari, toshewar albarkatun karfe yakan haifar da tsagewar tsayi. Tun da yawancin sassan karfe ana yin su ta hanyar mirgina, abubuwan da ba na zinariya ba, carbides, da dai sauransu a cikin karfe ana rarraba su tare da jagorancin nakasawa, yana haifar da karfe ya zama anisotropic. Misali, idan karfen kayan aiki yana da tsari irin na band, karfin karayar sa bayan kashewa shine 30% zuwa 50% karami fiye da karfin karaya mai tsayi. Idan akwai dalilai irin su abubuwan da ba na zinariya ba a cikin ƙarfe wanda ke haifar da damuwa, koda kuwa matsalolin tangential ya fi girma fiye da damuwa na axial, Tsawon tsayin tsayi yana da sauƙi don samuwa a ƙarƙashin ƙananan yanayi. Don haka, tsananin kulawa da matakin abubuwan da ba na ƙarfe ba da sukari a cikin ƙarfe shine muhimmin abu don hana ɓarna.

Halayen rarraba damuwa na ciki na ɓarkewar ɓarna da ɓarna arc sune: saman yana ƙarƙashin matsin lamba. Bayan barin farfajiyar don wani tazara, matsananciyar damuwa tana canzawa zuwa babban damuwa mai ƙarfi. Tsagewar yana faruwa a cikin yanki na danniya mai ƙarfi, sa'an nan kuma lokacin da damuwa na ciki Ya yada zuwa saman ɓangaren kawai idan an sake rarraba shi ko kuma raguwa na karfe ya kara karuwa.

Fassara mai jujjuyawa sau da yawa yana faruwa a cikin manyan sassan shaft, kamar rollers, rotors na injin turbine ko wasu sassan shaft. Halayen tsagewar sune cewa sun kasance daidai da hanyar axis kuma suna karya daga ciki zuwa waje. Ana yin su sau da yawa kafin a taurare kuma ana haifar da su ta hanyar zafi mai zafi. Manyan jabu sau da yawa suna da lahani na ƙarfe kamar pores, haɗawa, ƙirƙira fasa da fari. Wadannan lahani suna aiki a matsayin wurin farawa na karaya da karya a karkashin aikin danniya na axial. Ƙunƙarar Arc yana haifar da damuwa na zafi kuma yawanci ana rarraba su a cikin siffar baka a sassan da siffar ɓangaren ke canzawa. Yafi faruwa a cikin workpiece ko kusa da kaifi gefuna, tsagi da ramuka, kuma an rarraba a cikin wani baka siffar. Lokacin da manyan sassan ƙarfe na carbon da diamita ko kauri na 80 zuwa 100 mm ko fiye ba a kashe su ba, saman zai nuna damuwa mai matsawa kuma cibiyar za ta nuna damuwa. Damuwa, matsakaicin matsakaicin matsananciyar damuwa yana faruwa a cikin yanki na canzawa daga ƙwanƙwasa mai tauri zuwa maƙalar da ba ta da ƙarfi, kuma fashewar baka yana faruwa a waɗannan wurare. Bugu da ƙari, ƙimar sanyaya a gefuna masu kaifi da sasanninta yana da sauri kuma duk an kashe su. Lokacin canzawa zuwa sassa masu laushi, wato, zuwa wurin da ba a taurare ba, matsakaicin matsakaicin yanki na damuwa yana bayyana a nan, don haka tsagewar baka na iya faruwa. Matsakaicin sanyaya kusa da ramin fil, tsagi ko rami na tsakiya na workpiece yana jinkirin, madaidaicin madauri mai kauri yana da bakin ciki, kuma damuwa mai ƙarfi kusa da yankin tsaka mai ƙarfi na iya haifar da fashewar baka.

Tsage-tsalle na baya, wanda kuma aka sani da tsagewar ƙasa, tsagewar ƙasa ne. Zurfin fashewar ba shi da zurfi, yawanci kusan 0.01 ~ 1.5mm. Babban halayen wannan nau'in fashewar shi ne cewa jagorar sabani na fashewa ba shi da alaƙa da siffar ɓangaren. Ana haɗa tsaga da yawa da juna don samar da hanyar sadarwa kuma ana rarraba su sosai. Lokacin da zurfin tsaga ya fi girma, kamar fiye da 1 mm, halayen cibiyar sadarwa suna ɓacewa kuma su zama masu tsattsauran ra'ayi ba da gangan ba. Ƙwararrun hanyar sadarwa suna da alaƙa da yanayin damuwa mai girma biyu a saman.

High carbon ko carburized karfe sassa tare da decarburized Layer a saman suna yiwuwa ga samar da cibiyar sadarwa fasa a lokacin quenching. Wannan shi ne saboda saman saman yana da ƙananan abun ciki na carbon da ƙaramin ƙayyadaddun ƙayyadaddun ƙara fiye da na ciki na martensite. A lokacin quenching, saman Layer na carbide yana fuskantar damuwa mai ƙarfi. Sassan da ba a cire Layer na dephosphorization gaba ɗaya ba yayin sarrafa injina kuma za su haifar da tsagewar hanyar sadarwa yayin daɗaɗɗen wuta ko saman wuta. Don kauce wa irin wannan fasa, ya kamata a kula da ingancin farfajiyar sassan, kuma ya kamata a hana waldawar iskar shaka yayin maganin zafi. Bugu da kari, bayan an yi amfani da mutuƙar ƙirƙira na ɗan lokaci, tsagewar gajiyar zafin jiki da ke bayyana a cikin ɗigon ruwa ko hanyoyin sadarwa a cikin rami da tsagewar aikin niƙa na sassan da aka kashe duk suna cikin wannan nau'in.

Kwasfa yana faruwa a cikin kunkuntar yanki na saman Layer. Danniya mai matsananciyar damuwa yana aiki a cikin kwatancen axial da tangential, kuma damuwa mai ƙarfi yana faruwa a cikin jagorar radial. Fasassun suna layi ɗaya da saman ɓangaren. Fitar da taurin Layer bayan an sanyaya ɓangarorin da ke cikin ƙasa da kuma sassan da ake sanyaya. Abin da ya faru yana da alaƙa da tsarin da bai dace ba a cikin Layer mai tauri. Alal misali, bayan da aka sanyaya ƙarfe na ƙarfe na ƙarfe a wani ɗan gudun hijira, tsarin da ke cikin carburized Layer shine: Layer na waje na musamman pearlite + carbide, kuma sublayer shine martensite + saura Austenite, Layer na ciki yana da kyau pearlite ko kuma kyakkyawan tsarin pearlite. Tun da samuwar takamaiman girma na sub-Layer martensite shine mafi girma, sakamakon haɓakar ƙarar shine cewa damuwa mai ƙarfi yana aiki akan saman saman Layer a cikin kwatancen axial da tangential, kuma damuwa mai ƙarfi yana faruwa a cikin radial shugabanci, kuma maye gurbin damuwa yana faruwa a ciki, yana canzawa zuwa yanayin damuwa mai matsawa, da fashe fashe yana faruwa a cikin yankuna masu bakin ciki sosai inda damuwa ke canzawa sosai. Gabaɗaya, tsage-tsatse suna ɓoye cikin layi ɗaya da saman, kuma a cikin yanayi mai tsanani na iya haifar da bawon saman. Idan an ƙara haɓaka ko rage yawan kwantar da hankali na sassan carburized, za'a iya samun tsarin martensite na yau da kullun ko tsarin pearlite mai kyau a cikin Layer na carburized, wanda zai iya hana faruwar irin wannan fasa. Bugu da kari, a lokacin babban mitoci ko harshen wuta quenching, saman sau da yawa fiye da zafi da kuma rashin daidaituwa na tsarin tare da taurare Layer iya samar da irin wannan fasfot.

Microcracks sun bambanta da fasahohin huɗun da aka ambata a cikin abin da microstress ke haifar da su. Intergranular fasa da cewa bayyana bayan quenching, overheating da nika na high-carbon kayan aiki karfe ko carburized workpieces, kazalika da fasa lalacewa ta hanyar ba dace tempering na quenched sassa, duk suna da alaka da wanzuwar da kuma m fadada microcracks a cikin karfe.

Dole ne a bincika microcracks a ƙarƙashin na'urar microscope. Yawancin lokaci suna faruwa a kan iyakokin hatsi na austenite na asali ko a mahaɗin zanen gadon martensite. Wasu tsaga suna shiga cikin zanen gadon martensite. Bincike ya nuna cewa microcracks sun fi kowa a cikin tagwayen martensite. Dalilin shi ne cewa martensite flaky yana karo da juna lokacin da yake girma da sauri kuma yana haifar da damuwa. Duk da haka, tagwayen martensite kanta ba ta da ƙarfi kuma ba za ta iya haifar da nakasar filastik tana kwantar da damuwa ba, don haka cikin sauƙi yana haifar da microcracks. Hatsi na austenite suna da yawa kuma rashin ƙarfi ga microcracks yana ƙaruwa. Kasancewar microcracks a cikin karfe zai rage karfi da filastik na sassan da aka kashe, wanda zai haifar da lalacewa da wuri (karya) na sassan.

Don guje wa microcracks a cikin manyan sassan ƙarfe na carbon, ana iya ɗaukar matakan kamar ƙananan zafin zafi mai kashewa, samun kyakkyawan tsarin martensite, da rage abun cikin carbon a cikin martensite. Bugu da ƙari, lokacin fushi bayan quenching hanya ce mai mahimmanci don rage damuwa na ciki. Gwaje-gwaje sun tabbatar da cewa bayan isassun zafin jiki sama da 200 ° C, carbides da ke haɓakawa a fashe suna da tasirin "welding" da fasa, wanda zai iya rage haɗarin microcracks.

Abin da ke sama shine tattaunawa game da dalilai da hanyoyin rigakafi na tsagewa bisa tsarin rarraba rarraba. A cikin ainihin samarwa, rarraba tsagewa ya bambanta saboda dalilai kamar ingancin ƙarfe, siffar sashi, da fasahar sarrafa zafi da sanyi. Wasu lokuta fasa sun riga sun wanzu kafin maganin zafi kuma suna kara fadada yayin aikin kashewa; wani lokaci nau'ikan tsagewa da yawa na iya bayyana a sashi ɗaya a lokaci guda. A wannan yanayin, bisa ga morphological halaye na crack, macroscopic bincike na karaya surface, metallographic jarrabawa, da kuma lokacin da ya cancanta, da sinadaran bincike da kuma sauran hanyoyin ya kamata a yi amfani da su gudanar da wani m bincike daga kayan ingancin, tsari tsarin zuwa Sanadin zafi magani danniya don nemo crack. manyan abubuwan da ke haifar da sa'an nan kuma ƙayyade matakan rigakafi masu tasiri.

Binciken karaya na tsagewa hanya ce mai mahimmanci don nazarin abubuwan da ke haifar da fashewa. Duk wani karaya yana da wurin farawa don fasa. Kiyaye tsagewa yawanci suna farawa ne daga wurin haduwar fashewar radial.

Idan asalin fashewar ya kasance a saman sashin, yana nufin cewa tsagewar yana faruwa ne ta hanyar matsananciyar damuwa a saman. Idan babu lahani na tsari kamar haɗawa a saman, amma akwai abubuwan damuwa kamar alamomin wuka masu tsanani, sikelin oxide, sasanninta masu kaifi na sassan ƙarfe, ko sassan maye gurbi, fasa na iya faruwa.

Idan asalin fashe yana cikin ɓangaren, yana da alaƙa da lahani na kayan abu ko wuce kima na damuwa na juzu'i na ciki. Fagen karaya na quenching na al'ada shine launin toka da kuma ain mai kyau. Idan saman karaya ya kasance duhu launin toka da kuma m, yana faruwa ne ta hanyar zafi fiye da kima ko asalin nama yana da kauri.

Gabaɗaya magana, bai kamata a sami launi na oxidation akan ɓangaren gilashin quenching crack ba, kuma kada a sami ɓarna a kusa da fashewar. Idan akwai decarburization a kusa da fashewa ko wani launi mai oxidized a kan sashin tsage, yana nuna cewa sashin ya riga ya sami raguwa kafin ya ƙare, kuma ainihin fashewar za ta faɗaɗa ƙarƙashin rinjayar yanayin zafi. Idan ana ganin keɓaɓɓen carbide da haɗawa a kusa da ɓarna na ɓangaren, yana nufin cewa ɓarna suna da alaƙa da tsananin rarrabuwar kasusuwa a cikin albarkatun ƙasa ko kasancewar haɗawa. Idan tsaga kawai ya bayyana a kusurwoyi masu kaifi ko siffar maye gurbi na ɓangaren ba tare da abin da ke sama ba, yana nufin cewa tsagewar yana faruwa ne ta hanyar ƙirar tsari marar ma'ana na ɓangaren ko matakan da ba su dace ba don hana tsagewa, ko matsananciyar maganin zafi.

Bugu da kari, fasa a cikin maganin zafin sinadarai da sassa na quenching mafi yawa suna bayyana a kusa da taurare. Haɓaka tsarin daɗaɗɗen daɗaɗɗen da kuma rage matsalolin maganin zafi sune hanyoyi masu mahimmanci don kauce wa fashewar saman.

Lokacin aikawa: Mayu-22-2024