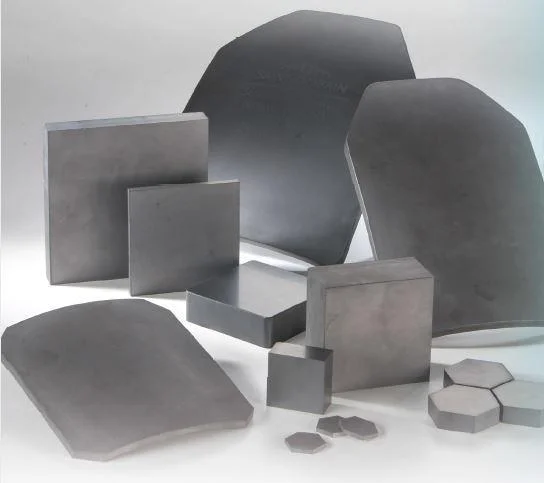

Silicon carbide tukwane da high zafin jiki ƙarfi, high zafin jiki hadawan abu da iskar shaka juriya, mai kyau lalacewa juriya, mai kyau thermal kwanciyar hankali, kananan coefficient na thermal fadadawa, high thermal watsin, high taurin, zafi girgiza juriya, sinadaran lalata juriya da sauran m Properties.An yi amfani da shi sosai a cikin mota, injiniyoyi, kariyar muhalli, fasahar sararin samaniya, na'urorin lantarki na bayanai, makamashi da sauran fannoni, kuma ya zama yumbun tsarin da ba za a iya maye gurbinsa ba tare da kyakkyawan aiki a yawancin masana'antu.Yanzu bari in nuna muku!

Rashin matsi

Ana ɗaukar sintering mara ƙarfi a matsayin hanya mafi ƙwaƙƙwarar hanya don sintering SiC.Dangane da nau'o'i daban-daban na sintering, za a iya raba matsi mara matsi zuwa matsi mai tsauri da ruwa-lokaci sintering.Ta hanyar ultra-lafiya β- A daidai adadin B da C (abincin oxygen kasa da 2%) an kara su zuwa SiC foda a lokaci guda, da s.proehazka ya zama sintered zuwa SiC sintered jiki tare da yawa sama da 98% a 2020 ℃.A. Mulla et al.An yi amfani da Al2O3 da Y2O3 azaman addittu kuma an haɗa su a 1850-1950 ℃ don 0.5 μ m β-SiC (bangaren barbashi ya ƙunshi ƙaramin adadin SiO2).Matsakaicin dangi na yumbura na SiC da aka samu ya fi 95% na ƙima mai yawa, kuma girman hatsi ƙarami ne kuma matsakaicin girman.Yana da 1.5 microns.

Zafafan latsa maɓalli

SiC mai tsafta ba za a iya ɓata shi kawai a cikin matsanancin zafin jiki ba tare da wasu abubuwan da za a iya haɗawa da su ba, don haka mutane da yawa suna aiwatar da tsarin matsi mai zafi don SiC.An sami rahotanni da yawa akan zazzafan matsi na SiC ta hanyar ƙara kayan taimako.Alliegro et al.Ya yi nazarin tasirin boron, aluminum, nickel, iron, chromium da sauran abubuwan karafa akan sinadari na SiC.Sakamakon ya nuna cewa aluminium da baƙin ƙarfe sune abubuwan da suka fi dacewa don haɓaka SiC zafi matsi sintering.FFlange yayi nazarin tasirin ƙara adadin Al2O3 daban-daban akan kaddarorin SiC mai zafi.An yi la'akari da cewa densification na zafi matsa SiC yana da alaka da tsarin rushewa da hazo.Koyaya, tsarin sintering mai zafi zai iya samar da sassan SiC kawai tare da sifa mai sauƙi.Yawan samfuran da aka samar ta hanyar aikin watsa shirye-shiryen zafi na lokaci ɗaya ba su da yawa, waɗanda ba su da amfani ga samar da masana'antu.

Hot isostatic latsa sintering

Domin shawo kan gazawar tsarin sintering na gargajiya, nau'in B-nau'in da nau'in C-nau'in an yi amfani da su azaman ƙari kuma an karɓi fasahar isostatic matsi mai zafi.A 1900 ° C, kyawawan yumburan crystalline tare da yawa fiye da 98 an samo su, kuma ƙarfin lanƙwasawa a dakin da zafin jiki zai iya kaiwa 600 MPa.Ko da yake zafi isostatic latsa sintering iya samar da m lokaci kayayyakin da hadaddun siffofi da kuma mai kyau inji Properties, da sintering dole ne a shãfe haske, wanda yake da wuya a cimma masana'antu samar.

Rashin amsawa

Reaction sintered silicon carbide, wanda kuma aka sani da kai bonded silicon carbide, yana nufin tsari a cikin abin da porous billet amsa da gas ko ruwa lokaci don inganta billet ingancin, rage porosity, da sinter gama kayayyakin tare da wani ƙarfi da girma daidaito.a dauki α- SiC foda da graphite ana gauraye su a wani kaso kuma a yi zafi zuwa kusan 1650 ℃ don samar da billet mai murabba'i.A lokaci guda, yana shiga ko shiga cikin billet ta hanyar Gaseous Si kuma yana amsawa tare da graphite don samar da β-SiC, haɗe tare da ɓoyayyun α-SiC.Lokacin da Si ke kutsawa gaba ɗaya, za'a iya samun amsawar jiki mai ƙima tare da cikakken yawa da girman rashin raguwa.Idan aka kwatanta da sauran matakai na sintering, girman canjin amsawar amsawa a cikin tsarin densification yana da ƙananan, kuma ana iya shirya samfurori tare da girman girman.Duk da haka, kasancewar babban adadin SiC a cikin jikin da aka lalata yana sa kaddarorin zafin jiki na amsawa sintered yumbura SiC mafi muni.

Lokacin aikawa: Juni-08-2022