1. Rashin hankali

Abubuwan brazing na aluminum da aluminum alloys ba su da kyau, musamman saboda fim din oxide a saman yana da wuya a cire.Aluminum yana da alaƙa da iskar oxygen.Yana da sauƙi don samar da wani m, barga da kuma high narkewa batu oxide film Al2O3 a kan surface.A lokaci guda kuma, aluminium alloys dauke da magnesium kuma za su samar da fim din oxide MgO sosai.Za su da gaske hana wetting da yada solder.Kuma da wuya a cire.A lokacin brazing, aikin brazing za a iya aiwatar da shi kawai tare da juzu'i mai kyau.

Abu na biyu, aikin aluminum da aluminum gami brazing yana da wahala.Matsayin narkewar aluminium da alloy na aluminium bai bambanta da na ƙarfe mai cike da brazing da ake amfani da shi ba.Matsakaicin zafin jiki na zaɓi don brazing yana da kunkuntar sosai.Ƙananan kula da zafin jiki ba daidai ba yana da sauƙi don haifar da zafi ko ma narkewar karfen tushe, yana sa aikin brazing yana da wahala.Wasu allunan aluminium da aka ƙarfafa ta hanyar maganin zafi kuma za su haifar da abubuwa masu tausasawa kamar tsufa ko ɓata lokaci saboda dumama brazing, wanda zai rage kaddarorin haɗin gwiwa.A lokacin brazing na harshen wuta, yana da wuya a yi la'akari da zafin jiki saboda launi na aluminum alloy ba ya canzawa yayin dumama, wanda kuma yana ƙara yawan buƙatun matakin aikin mai aiki.

Bugu da ƙari, juriya na lalata aluminum da aluminum gami brazed gidajen abinci yana da sauƙin shafar karafa da juzu'i.Ƙarfin wutar lantarki na aluminum da aluminum gami ya bambanta da na solder, wanda ke rage juriya na lalata na haɗin gwiwa, musamman ga haɗin gwiwa mai laushi.Bugu da ƙari, yawancin juzu'in da aka yi amfani da su a cikin brazing na aluminum da aluminum gami suna da lalata mai ƙarfi.Ko da an tsabtace su bayan brazing, tasirin juriya akan juriya na lalata ba za a kawar da su gaba ɗaya ba.

2. Brazing abu

(1) Brazing na aluminum da aluminum gami hanya ce da ba kasafai ake amfani da ita ba, saboda abun da ke ciki da yuwuwar wutar lantarki na ƙarfe mai filler da ƙarfe mai tushe sun bambanta sosai, wanda ke da sauƙin haifar da lalatawar haɗin gwiwa.The taushi soldering yafi rungumi zinc tushen solder da tin gubar solder, wanda za a iya raba zuwa low zazzabi solder (150 ~ 260 ℃), matsakaici zazzabi solder (260 ~ 370 ℃) da kuma high zafin jiki solder (370 ~ 430 ℃) bisa ga yanayin zafi.Lokacin da aka yi amfani da siyar da gubar dalma da jan ƙarfe ko nickel an riga an sanya shi a saman saman aluminum don yin brazing, za a iya hana lalata a wurin haɗin gwiwa, don inganta juriya na lalata haɗin gwiwa.

Ana amfani da brazing na aluminum da aluminum gami, kamar jagorar tacewa, evaporator, radiator da sauran abubuwan da aka gyara.Za a iya amfani da karafa masu filaye na aluminium kawai don brazing na aluminium da aluminium, daga cikinsu waɗanda aka fi amfani da ƙarfe na silicon filler.Ana nuna ƙayyadaddun iyakokin aikace-aikacen da ƙarfin juzu'i na haɗin gwiwar brazed a cikin Table 8 da tebur 9 bi da bi.Duk da haka, wurin narkewa na wannan solder yana kusa da na karfen tushe, don haka zafin zafin jiki ya kamata a kula da shi sosai a lokacin brazing don guje wa zafi ko ma narkewar karfen tushe.

Teburin 8 na aikace-aikacen ƙarfe na brazing na aluminium da aluminium

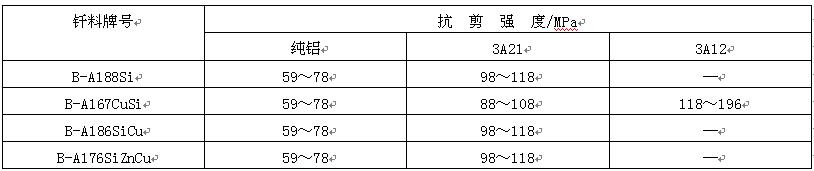

Tebur 9 ƙarfin ƙarfi na aluminium da haɗin gwiwa na aluminium wanda aka yi da ƙarfe na siliki na aluminium

Aluminum silicon solder yawanci ana kawo shi ta hanyar foda, manna, waya ko takarda.A wasu lokuta, solder hada faranti tare da aluminum a matsayin core da aluminum silicon solder kamar yadda ake amfani da cladding.Irin wannan nau'in farantin ɗin da aka haɗa ana yin ta ta hanyar injin ruwa kuma galibi ana amfani da shi azaman ɓangaren abubuwan brazing.A lokacin brazing, ƙarfen filler ɗin brazing akan farantin ɗin ya narke kuma yana gudana ƙarƙashin aikin capillary da nauyi don cike gibin haɗin gwiwa.

(2) Flux da garkuwar gas don aluminum da aluminum gami brazing, ana amfani da juzu'i na musamman don cire fim ɗin.Ana amfani da jujjuyawar kwayoyin halitta bisa triethanolamine, kamar fs204, tare da solder mai laushi mai ƙarancin zafi.Amfanin wannan juzu'i shine cewa yana da ɗan lalacewa akan ƙarfe na tushe, amma zai samar da iskar gas mai yawa, wanda zai shafi jiko da caulking na solder.Ana amfani da jujjuyawar amsawa dangane da zinc chloride, kamar fs203 da fs220a, tare da matsakaicin zafin jiki da babban zafin solder mai taushi.Juyin da ke aiki yana da lalacewa sosai, kuma dole ne a cire ragowar sa bayan an yi tagulla.

A halin yanzu, brazing na aluminum da aluminum gami har yanzu yana mamaye da cire fim mai juyi.Juyin brazing da aka yi amfani da shi ya haɗa da tushen chloride da fluoride na tushen fluoride.Tushen tushen chloride yana da ƙarfi mai ƙarfi don cire fim ɗin oxide da ruwa mai kyau, amma yana da babban tasiri mai lalata akan ƙarfen tushe.Dole ne a cire ragowar sa gaba ɗaya bayan brazing.Tushen fluoride sabon nau'in juyi ne, wanda ke da tasirin cire fim mai kyau kuma ba shi da lalata ga ƙarfe mai tushe.Duk da haka, yana da babban wurin narkewa da rashin kwanciyar hankali na zafi, kuma za'a iya amfani dashi kawai tare da siliki na aluminum.

Lokacin brazing aluminum da aluminum gami, injin, tsaka tsaki ko inert yanayi yawanci ana amfani da.Lokacin da aka yi amfani da vacuum brazing, matakin injin zai kai ga tsari na 10-3pa.Lokacin da ake amfani da iskar nitrogen ko argon don kariya, dole ne tsarkinsa ya yi girma sosai, kuma raɓar raɓa dole ne ya zama ƙasa da -40 ℃.

3. Fasahar Brazing

Brazing na aluminum da aluminum gami yana da babban buƙatu don tsaftacewa na workpiece surface.Domin samun inganci mai kyau, dole ne a cire tabon mai da fim din oxide a saman kafin a yi tagulla.Cire tabon mai a saman tare da maganin ruwa na Na2CO3 a zazzabi na 60 ~ 70 ℃ na 5 ~ 10min, sa'an nan kuma kurkura da ruwa mai tsabta;Za a iya cire fim din oxide ta hanyar etching tare da maganin ruwa na NaOH a zazzabi na 20 ~ 40 ℃ na 2 ~ 4min, sannan a wanke da ruwan zafi;Bayan cire tabon mai da fim din oxide a saman, za a bi da aikin aikin tare da maganin ruwa na HNO3 don mai sheki na 2 ~ 5min, sannan a tsaftace shi a cikin ruwa mai gudu kuma a ƙarshe ya bushe.Ba za a taɓa kayan aikin da aka yi amfani da su ta hanyar waɗannan hanyoyin ba ko gurɓata su da wasu datti, kuma za a yi brazed a cikin 6 ~ 8h.Zai fi kyau a yi braze nan da nan idan zai yiwu.

Hanyoyin brazing na aluminum da aluminum gami sun haɗa da brazing na harshen wuta, walƙiyar ƙarfe da tanderu.Waɗannan hanyoyin gabaɗaya suna amfani da juzu'i a cikin brazing, kuma suna da ƙaƙƙarfan buƙatu akan dumama zafin jiki da riƙe lokaci.A lokacin brazing na harshen wuta da kuma siyar da ƙarfe na ƙarfe, guje wa dumama raɗaɗin kai tsaye ta tushen zafi don hana juyin daga zafi da gazawa.Tun da ana iya narkar da aluminum a cikin solder mai laushi tare da babban abun ciki na zinc, ya kamata a dakatar da dumama da zarar an kafa haɗin gwiwa don guje wa lalata karfen tushe.A wasu lokuta, brazing na aluminum da aluminum gami wani lokacin ba ya amfani da juyi, amma yana amfani da ultrasonic ko scraping hanyoyin don cire fim din.Lokacin amfani da scraping don cire fim ɗin don brazing, da farko zazzage kayan aikin zuwa zafin brazing, sa'an nan kuma goge ɓangaren brazing na aikin tare da ƙarshen sandar siyar (ko kayan aikin gogewa).Yayin da ake karya fim din oxide, ƙarshen mai siyar zai narke kuma ya jika karfen tushe.

Hanyoyin brazing na aluminum da aluminum gami sun haɗa da brazing na harshen wuta, tanderu brazing, tsoma brazing, vacuum brazing da gas garkuwa brazing.Ana amfani da brazing na harshen wuta galibi don ƙananan kayan aiki da samarwa guda ɗaya.Don kauce wa gazawar juzu'i saboda hulɗar tsakanin ƙazanta a cikin acetylene da juyi lokacin amfani da harshen wuta na oxyacetylene, yana da kyau a yi amfani da wutar lantarki da aka matsa man fetur tare da ɗan raguwa don hana iskar oxygenation na tushe karfe.A lokacin takamaiman brazing, ana iya sanya jujjuyawar brazing da ƙarfe mai filler a wurin da aka yi wa braz a gaba kuma a yi zafi a lokaci guda tare da kayan aikin;Hakanan za'a iya mai da kayan aikin zuwa zafin jiki na brazing da farko, sa'an nan kuma za'a iya aika mai siyar da aka tsoma tare da juzu'i zuwa matsayin brazing;Bayan an narkar da juzu'i da karfen filler, za a cire wutar dumama sannu a hankali bayan an cika ƙarfen filler daidai gwargwado.

Lokacin brazing aluminum da aluminum gami a cikin tanderun iska, brazing filler karfe za a saita saiti, kuma brazing juzu'i za a narke a cikin distilled ruwa don shirya wani lokacin farin ciki bayani tare da maida hankali na 50% ~ 75%, sa'an nan kuma mai rufi ko fesa a kan. da brazing surface.Hakanan za'a iya rufe adadin da ya dace na foda brazing juzu'in a kan ƙarfe mai cike da brazing da saman brazing, sa'an nan kuma za a sanya walƙar da aka haɗa a cikin tanderun don dumama brazing.Don hana tushen karfe daga zafi ko ma narkewa, dole ne a sarrafa zafin zafin jiki sosai.

Ana amfani da manna ko mai sayar da foil gabaɗaya don tsoma brazing na aluminum da aluminum gami.Kayan aikin da aka haɗa za a yi preheated kafin brazing don sanya zafinsa kusa da zafin brazing, sa'an nan kuma a nutsar da shi cikin juzu'in brazing don brazing.Lokacin brazing, zafin brazing da lokacin brazing dole ne a sarrafa su sosai.Idan zafin jiki ya yi yawa, ƙarfe na tushe yana da sauƙi don narkewa kuma mai siyar yana da sauƙi a rasa;Idan zafin jiki ya yi ƙasa sosai, mai siyarwar bai narke sosai ba, kuma ƙimar brazing yana raguwa.Za a ƙididdige zafin jiki na brazing bisa ga nau'i da girman ƙarfen tushe, abun da ke ciki da wurin narkewar ƙarfen filler, kuma gabaɗaya yana tsakanin zafin jiki na ruwa mai filler da zafin jiki mai ƙarfi na ƙarfen tushe.Lokacin tsoma kayan aikin a cikin wanka mai juyi dole ne tabbatar da cewa mai siyar zai iya narke sosai kuma ya kwarara, kuma lokacin tallafi bai kamata ya yi tsayi da yawa ba.In ba haka ba, sinadarin silicon da ke cikin abin siyar zai iya yaɗuwa cikin ƙarfen tushe, wanda zai sa ƙarfen tushe kusa da kabu.

A cikin injin daskarewa na aluminium da aluminium alloys, ana amfani da masu kunna aikin ƙarfe sau da yawa don gyara fim ɗin oxide na aluminum da kuma tabbatar da wetting da yada solder.Magnesium za a iya kai tsaye amfani da workpiece a cikin nau'i na barbashi, ko gabatar a cikin brazing zone a cikin nau'i na tururi, ko magnesium za a iya kara da aluminum silicon solder a matsayin gami kashi.Domin workpiece tare da hadaddun tsari, domin tabbatar da cikakken tasirin magnesium tururi a kan tushe karfe da kuma inganta brazing ingancin, gida garkuwa tsari sau da yawa daukan matakan, wato, da workpiece da farko sanya a cikin wani bakin karfe akwatin (na kowa). wanda aka sani da akwatin tsari), sannan a sanya shi a cikin tanderun da ba za a iya amfani da shi ba don dumama brazing.Vacuum Brazed Aluminum da aluminum gami gidajen abinci suna da santsi mai santsi da haɗin gwiwa mai yawa, kuma baya buƙatar tsaftacewa bayan brazing;Duk da haka, kayan aikin motsa jiki yana da tsada, kuma tururin magnesium yana lalata wutar lantarki da gaske, don haka yana buƙatar tsaftacewa da kiyaye shi akai-akai.

Lokacin brazing aluminum da aluminum gami a tsaka tsaki ko inert yanayi, magnesium activator ko flux za a iya amfani da su cire fim.Lokacin da ake amfani da mai kunnawa magnesium don cire fim ɗin, adadin magnesium da ake buƙata ya fi ƙasa da na vacuum brazing.Gabaɗaya, w (mg) shine kusan 0.2% ~ 0.5%.Lokacin da abun ciki na magnesium yana da girma, za a rage ingancin haɗin gwiwa.Hanyar brazing NOCOLOK ta amfani da fluoride flux da kariya ta nitrogen wata sabuwar hanya ce da aka haɓaka cikin sauri a cikin 'yan shekarun nan.Tun da ragowar fluoride ba ya sha danshi kuma baya lalatawa zuwa aluminum, ana iya barin tsarin cire ragowar ruwa bayan brazing.Ƙarƙashin kariyar nitrogen, ƙaramin adadin fluoride kawai yana buƙatar a rufe shi, ƙarfe na filler zai iya jika karfen tushe da kyau, kuma yana da sauƙi a sami haɗin haɗin gwiwa mai inganci.A halin yanzu, an yi amfani da wannan hanyar brazing na NOCOLOK a cikin yawan samar da radiator na aluminum da sauran abubuwan da aka gyara.

Don aluminium da aluminium da aka yi brazed tare da juzu'i ban da fluoride flux, ragowar juyi dole ne a cire gaba ɗaya bayan brazing.Ragowar juzu'in brazing na aluminium za a iya wanke shi tare da maganin kwayoyin halitta irin su methanol da trichlorethylene, a cire shi da maganin ruwa na sodium hydroxide, sannan a tsaftace shi da ruwan zafi da sanyi.Chloride shine ragowar brazing flux don aluminum, wanda za'a iya cire shi bisa ga hanyoyi masu zuwa;Da farko, jiƙa a cikin ruwan zafi a 60 ~ 80 ℃ na minti 10, a hankali tsaftace ragowar a kan haɗin gwiwa tare da goga, kuma tsaftace shi da ruwan sanyi;Sannan a jika shi a cikin maganin ruwa na nitric acid 15% na tsawon mintuna 30, sannan a wanke shi da ruwan sanyi.

Lokacin aikawa: Juni-13-2022