1. Rashin hankali

Yana da wuya a yi amfani da yumbu da yumbu, yumbu da kayan ƙarfe.Yawancin masu siyar suna samar da ball a saman yumbu, tare da ɗan ko babu jika.Ƙarfin filler ɗin brazing wanda zai iya jika yumbu yana da sauƙi don samar da nau'ikan mahadi iri-iri (kamar carbides, silicides da ternary ko multivariate mahadi) a haɗin haɗin gwiwa yayin brazing.Kasancewar waɗannan mahadi yana rinjayar kayan aikin injiniya na haɗin gwiwa.Bugu da ƙari, saboda babban bambanci na haɓakar haɓakawar thermal a tsakanin yumbu, ƙarfe da solder, za a sami raguwar damuwa a cikin haɗin gwiwa bayan an kwantar da zafin jiki na brazing zuwa dakin da zafin jiki, wanda zai iya haifar da fashewar haɗin gwiwa.

Za a iya inganta wettability na solder a kan yumbura ta hanyar ƙara abubuwa masu aiki na karfe zuwa ga kowa da kowa;Ƙananan zafin jiki da ɗan gajeren lokaci brazing na iya rage tasirin amsawar dubawa;Za'a iya rage damuwa na thermal na haɗin gwiwa ta hanyar zayyana nau'in haɗin gwiwa mai dacewa da yin amfani da nau'i-nau'i ko nau'i-nau'i mai yawa a matsayin matsakaicin matsakaici.

2. Mai siyarwa

yumbu da ƙarfe yawanci ana haɗa su a cikin tanderu mai amfani ko hydrogen da tanderun argon.Baya ga halaye na gabaɗaya, ƙarfe mai cike da brazing don injin injin na'urorin lantarki shima yakamata ya sami wasu buƙatu na musamman.Misali, mai siyarwar bai kamata ya ƙunshi abubuwan da ke haifar da matsanancin tururi ba, don kada ya haifar da ɗigon dielectric da guba na na'urori.Gabaɗaya an ƙayyade cewa lokacin da na'urar ke aiki, matsa lamba na mai siyar ba zai wuce 10-3pa ba, kuma ƙazantaccen tururi da ke ƙunshe ba zai wuce 0.002% ~ 0.005%;W (o) na mai siyar ba zai wuce 0.001% ba, don kauce wa tururin ruwa da aka samar yayin brazing a cikin hydrogen, wanda zai iya haifar da zubar da narkakken solder;Bugu da ƙari, mai siyarwar dole ne ya kasance mai tsabta kuma ba tare da oxides na saman ba.

Lokacin brazing bayan yumbu na ƙarfe, jan ƙarfe, tushe, jan ƙarfe na azurfa, jan ƙarfe na gwal da sauran ƙarfe na ƙarfe na ƙarfe na ƙarfe za a iya amfani da su.

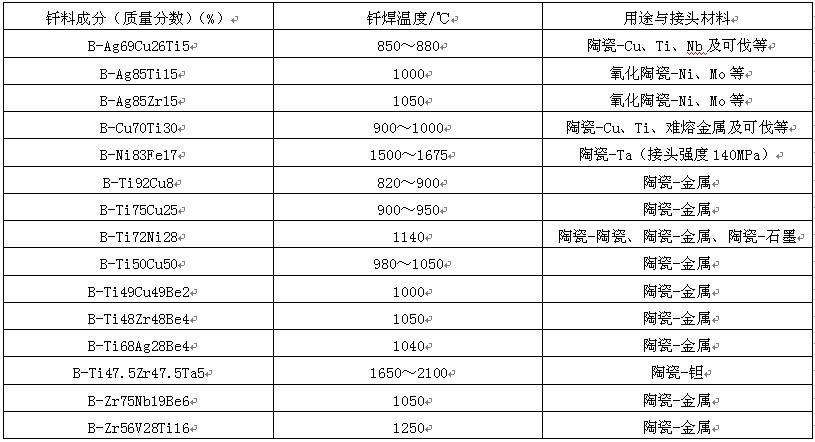

Don yin brazing kai tsaye na yumbu da karafa, za a zaɓi karafa na filler masu ɗauke da abubuwa masu aiki Ti da Zr.Ƙarfan filler na binary sun fi Ti Cu da Ti Ni, waɗanda za a iya amfani da su a 1100 ℃.Daga cikin ternary solder, Ag Cu Ti (W) (TI) shi ne mafi yawan amfani da solder, wanda za a iya amfani da kai tsaye brazing na daban-daban yumbu da karafa.Za'a iya amfani da ƙarfen filler na ternary ta foil, foda ko Ag Cu eutectic filler ƙarfe tare da Ti foda.B-ti49be2 brazing filler karfe yana da irin wannan juriyar lalata ga bakin karfe da ƙarancin tururi.Ana iya zaɓin shi da kyau a cikin mahaɗar injin rufewa tare da iskar oxygen da juriya.A cikin ti-v-cr solder, zafi mai narkewa shine mafi ƙanƙanta (1620 ℃) lokacin da w (V) shine 30%, kuma ƙari na Cr zai iya rage yawan zafin jiki mai narkewa.B-ti47.5ta5 solder ba tare da Cr da aka yi amfani da kai tsaye brazing na alumina da magnesium oxide, da kuma ta hadin gwiwa iya aiki a yanayin zafi na 1000 ℃.Tebur 14 yana nuna motsi mai aiki don haɗin kai tsaye tsakanin yumbu da ƙarfe.

Tebur 14 mai aiki na brazing filler don yumbu da brazing karfe

2. Fasahar Brazing

Za'a iya goge yumburan da aka riga aka yi ƙarfe a cikin iskar gas mai tsafta, hydrogen ko mahalli.Ana amfani da Vacuum brazing gabaɗaya don yin brazing kai tsaye na yumbu ba tare da ƙarfe ba.

(1) Universal brazing tsari na duniya brazing tsari na yumbu da karfe za a iya raba bakwai matakai: surface tsaftacewa, manna shafi, yumbu surface metallization, nickel plating, brazing da post weld dubawa.

Manufar tsaftacewa shine don cire tabon mai, gumi da kuma fim din oxide akan saman karfen tushe.Sassan karfe da solder za a fara raguwa, sannan a cire fim din oxide ta hanyar wanke acid ko alkali, a wanke da ruwa mai gudana kuma a bushe.Sassan da ke da manyan buƙatu za a bi da su da zafi a cikin tanderu mai ƙima ko tanderun hydrogen (hanyar bombardment kuma za a iya amfani da su) a cikin zafin jiki da lokacin da ya dace don tsarkake saman sassan.Sassan da aka tsaftace ba za su yi hulɗa da abubuwa masu maiko ko hannaye ba.Nan da nan za a saka su cikin tsari na gaba ko a cikin injin bushewa.Ba za a iya fallasa su cikin iska na dogon lokaci ba.Za a tsaftace sassan yumbura tare da acetone da ultrasonic, a wanke da ruwa mai gudana, sannan a karshe a tafasa sau biyu tare da ruwa mai narkewa na 15min kowane lokaci.

Manna shafi wani muhimmin tsari ne na ƙarfe na yumbu.A lokacin da ake shafa, ana amfani da shi a saman yumbu don a sanya shi da goga ko na'ura mai shafa.A shafi kauri ne kullum 30 ~ 60mm.Ana shirya manna gabaɗaya daga tsantsar foda mai tsabta (wani lokaci ana ƙara oxide ƙarfe mai dacewa) tare da girman barbashi na kusan 1 ~ 5um da mannen kwayoyin halitta.

Ana aika sassan yumbu da aka liƙa zuwa tanderun hydrogen kuma a sanya su tare da rigar hydrogen ko fashewar ammonia a 1300 ~ 1500 ℃ na 30 ~ 60min.Don sassan yumbu mai rufi da hydrides, za a yi zafi da su zuwa kusan 900 ℃ don lalata hydrides kuma su amsa da ƙarfe mai tsabta ko titanium (ko zirconium) wanda ya rage a saman yumbu don samun rufin ƙarfe a saman yumbu.

Domin Mo Mn da aka yi da karfe, domin a jika shi tare da solder, dole ne a sanya wani Layer na nickel na 1.4 ~ 5um na lantarki ko kuma a shafe shi da Layer na nickel foda.Idan brazing zafin jiki ne kasa da 1000 ℃, da nickel Layer na bukatar a riga sintered a cikin wani hydrogen tanderu.Matsakaicin zafin jiki da lokacin shine 1000 ℃ / 15 ~ 20min.

Abubuwan yumbun da aka kula da su sassa ne na ƙarfe, waɗanda za a haɗa su gaba ɗaya tare da bakin karfe ko graphite da yumbu.Za a shigar da solder a gidajen haɗin gwiwa, kuma aikin aikin zai kasance mai tsabta a duk lokacin aikin, kuma kada a taɓa shi da hannu.

Za a yi brazing a cikin tanderun argon, hydrogen ko tanderu.Matsakaicin zafin jiki na brazing ya dogara da karfen filler.Don hana faɗuwar sassan yumbu, yawan sanyaya ba zai yi sauri ba.Bugu da kari, brazing kuma na iya amfani da wani matsa lamba (kimanin 0.49 ~ 0.98mpa).

Baya ga duba ingancin saman, weld ɗin brazed kuma za su kasance ƙarƙashin girgiza zafin zafi da duba kadarorin inji.Sassan hatimi don na'urorin mara amfani dole ne su kasance ƙarƙashin gwajin ɗigon ruwa bisa ga ƙa'idodin da suka dace.

(2) Yin brazing kai tsaye lokacin brazing kai tsaye (hanyar ƙarfe mai aiki), da farko tsaftace saman yumbu da walda na ƙarfe, sannan a haɗa su.Don guje wa faɗuwar abubuwa daban-daban na haɓakar haɓakar thermal na kayan sassa, ana iya jujjuya Layer ɗin buffer (daya ko fiye yadudduka na zanen ƙarfe) tsakanin walda.Ƙarfen filler ɗin brazing za a matse shi tsakanin walda biyu ko kuma a sanya shi a wurin da tazarar ke cike da ƙarfe mai jujjuyawar brazing gwargwadon yiwuwa, sannan za a aiwatar da brazing kamar na yau da kullun.

Idan an yi amfani da siyar da Ag Cu Ti don brazing kai tsaye, za a ɗauki hanyar brazing.Lokacin da injin injin digiri a cikin tanderun ya kai 2.7 × Fara dumama a 10-3pa, kuma zafin jiki na iya tashi da sauri a wannan lokacin;Lokacin da zafin jiki yana kusa da wurin narkewa na mai siyar, yakamata a ɗaga zafin jiki a hankali don sanya yawan zafin jiki na duk sassan walda ya zama iri ɗaya;Lokacin da mai siyar ya narke, za a ɗaga zafin jiki da sauri zuwa zafin brazing, kuma lokacin riƙewa zai zama 3 ~ 5min;A lokacin sanyaya, za a sanyaya a hankali kafin 700 ℃, kuma za a iya sanyaya ta halitta da tanderun bayan 700 ℃.

Lokacin da Ti Cu mai aiki da solder ke daɗaɗa kai tsaye, nau'in siyar zai iya zama Cu foil da Ti foda ko sassa na Cu da Ti foil, ko kuma ana iya shafa saman yumbu da Ti foda da Cu foil.Kafin brazing, duk sassa na ƙarfe za a lalata su ta hanyar vacuum.The degassing zafin jiki na oxygen free jan karfe zai zama 750 ~ 800 ℃, da Ti, Nb, Ta, da dai sauransu za a degassed a 900 ℃ for 15min.A wannan lokacin, injin injin ba zai zama ƙasa da 6.7 × 10-3Pa ba. A lokacin brazing, tara abubuwan da za a yi amfani da su a cikin ƙayyadaddun, sanya su cikin tanderun injin zuwa 900 ~ 1120 ℃, kuma lokacin riƙewa shine 2 ~ 5 min.A lokacin duk aikin brazing, matakin injin ba zai zama ƙasa da 6.7 × 10-3Pa ba.

Tsarin brazing na hanyar Ti Ni yayi kama da na Ti Cu, kuma zafin brazing shine 900 ± 10 ℃.

(3) Hanyar brazing oxide oxide brazing hanya ce don gane ingantaccen haɗin gwiwa ta amfani da lokacin gilashin da aka samar ta hanyar narkewar solder oxide don kutsawa cikin tukwane da jika saman ƙarfe.Yana iya haɗa yumbu tare da yumbu da yumbu da ƙarfe.Karfe na brazing na oxide sun ƙunshi Al2O3, Cao, Bao da MgO.Ta ƙara B2O3, Y2O3 da ta2o3, ana iya samun karafa masu cike da brazing tare da wuraren narkewa daban-daban da ƙididdigar faɗaɗa madaidaiciya.Bugu da kari, fluoride brazing filler karafa tare da CaF2 da NaF a matsayin manyan abubuwan kuma ana iya amfani da su don haɗa yumbu da karafa don samun haɗin gwiwa tare da babban ƙarfi da ƙarfin zafi.

Lokacin aikawa: Juni-13-2022