1. Mai siyarwa

Kowane irin solders da zazzabi kasa da 3000 ℃ za a iya amfani da W brazing, da kuma jan karfe ko azurfa tushen solders za a iya amfani da aka gyara tare da zazzabi kasa da 400 ℃;Tushen zinari, tushen manganese, tushen manganese, tushen palladium ko madaidaicin madaidaicin ƙarfe ana amfani da su don abubuwan da aka yi amfani da su tsakanin 400 ℃ da 900 ℃;Don abubuwan da aka yi amfani da su sama da 1000 ℃, ana amfani da ƙarfe masu tsabta kamar Nb, Ta, Ni, Pt, PD da Mo.Yawan zafin jiki na kayan aikin da aka yi tare da kayan aikin platinum ya kai 2150 ℃.Idan 1080 ℃ yaduwa magani da aka za'ayi bayan brazing, matsakaicin aiki zafin jiki zai iya kai 3038 ℃.

Yawancin masu siyar da aka yi amfani da su don brazing w ana iya amfani da su don brazing Mo, kuma ana iya amfani da masu siyar da jan ƙarfe ko azurfa don abubuwan Mo waɗanda ke aiki ƙasa da 400 ℃;Don na'urorin lantarki da sassan da ba na tsarin aiki a 400 ~ 650 ℃, Cu Ag, Au Ni, PD Ni ko Cu Ni solders za a iya amfani da;Tushen Titanium ko wasu tsantsar ƙarfe mai cike da ƙarfe tare da manyan wuraren narkewa ana iya amfani da su don abubuwan da ke aiki a yanayin zafi mafi girma.Ya kamata a lura da cewa tushen manganese, tushen cobalt da nickel tushen karafa masu cike da nickel gabaɗaya ba a ba da shawarar don gujewa samuwar mahadi na tsaka-tsakin tsaka-tsaki a cikin gidajen haɗin gwiwar brazing ba.

Lokacin da aka yi amfani da abubuwan TA ko Nb a ƙasa da 1000 ℃, tushen jan ƙarfe, tushen manganese, tushen cobalt, tushen titanium, tushen nickel, tushen gwal da alluran palladium ana iya zaɓar, gami da Cu Au, Au Ni, PD Ni da Pt Au_ Ni da Masu siyar da Cu Sn suna da ingantaccen wettability zuwa TA da Nb, mai kyau brazing kabu kafa da babban haɗin gwiwa ƙarfi.Kamar yadda karafa masu filaye da azurfa sukan sa karafa masu karyewa, ya kamata a guji su gwargwadon yiwuwa.Don abubuwan da aka yi amfani da su tsakanin 1000 ℃ da 1300 ℃, ƙarfe mai tsabta Ti, V, Zr ko gami dangane da waɗannan karafa waɗanda ke samar da ƙarfi mara iyaka da ruwa tare da su za a zaɓi su azaman ƙarfe mai cike da brazing.Lokacin da zafin sabis ya fi girma, za'a iya zaɓar karfen mai mai ɗauke da HF.

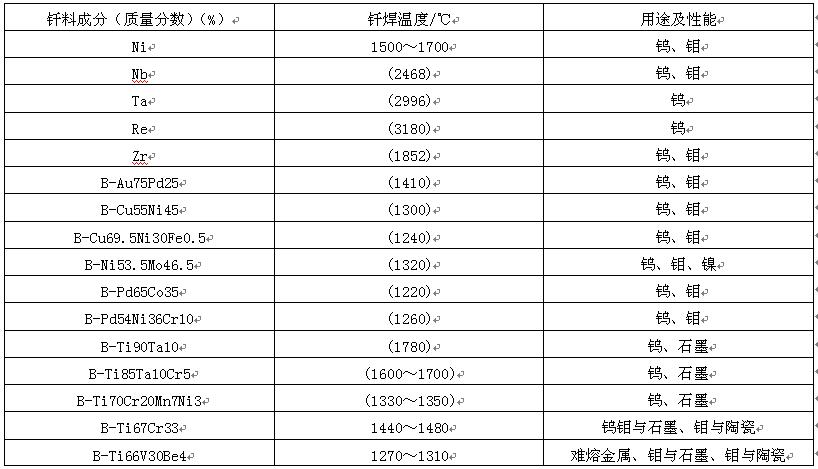

W. Dubi tebur 13 don karafa masu filler na Mo, Ta da Nb a babban zafin jiki.

Tebur 13 brazing filler karafa don tsananin zafin zafin brazing na karafa masu jujjuyawa

Kafin brazing, ana buƙatar a hankali cire oxide akan saman ƙarfe mai jujjuyawa.Ana iya amfani da niƙa na inji, fashewar yashi, tsaftacewa na ultrasonic ko tsabtace sinadarai.Za a yi brazing nan da nan bayan aikin tsaftacewa.

Saboda ɓacin rai na asali na W, sassan w za a sarrafa su a hankali a cikin aikin haɗakarwa don guje wa karyewa.Don hana samuwar tungsten carbide gaggautsa, ya kamata a guji hulɗar kai tsaye tsakanin W da graphite.Prestressing saboda kafin sarrafa walda ko walda za a shafe kafin waldi.W yana da sauƙin oxidize lokacin da zafin jiki ya tashi.Digiri na injin ya zama babba lokacin brazing.Lokacin da aka yi brazing a cikin kewayon zafin jiki na 1000 ~ 1400 ℃, ƙimar injin ba zai zama ƙasa da 8 × 10-3Pa ba. maganin yaduwa bayan walda.Misali, b-ni68cr20si10fel solder ana amfani da shi don braze W a 1180 ℃.Bayan uku watsa jiyya na 1070 ℃ / 4h, 1200 ℃ / 3.5h da 1300 ℃ / 2h bayan waldi, da sabis zafin jiki na brazed hadin gwiwa iya isa fiye da 2200 ℃.

Ya kamata a yi la'akari da ƙananan haɓakar haɓakawar thermal lokacin haɗa haɗin haɗin gwiwa na Mo, kuma ratar haɗin gwiwa ya kamata ya kasance tsakanin kewayon 0.05 ~ 0.13MM.Idan an yi amfani da kayan aiki, zaɓi abu tare da ƙaramin haɓakar haɓakar zafi.Mo recrystallization yana faruwa a lokacin da brazing na harshen wuta, sarrafa yanayi tanderu, vacuum makera, induction tanderu da juriya dumama wuce recrystallization zafin jiki ko recrystallization zafin jiki ya ragu saboda yaduwar solder abubuwa.Sabili da haka, lokacin da zafin jiki na brazing yana kusa da zazzabi na recrystallization, guntun lokacin brazing, mafi kyau.Lokacin brazing sama da yanayin recrystallization na Mo, lokacin brazing da adadin sanyaya dole ne a sarrafa shi don gujewa fashewa sakamakon saurin sanyi.Lokacin da aka yi amfani da brazing na harshen wuta na oxyacetylene, yana da kyau a yi amfani da gaurayawan juzu'i, wato, borate masana'antu ko na azurfa brazing flux tare da matsanancin zafi mai ɗauke da calcium fluoride, wanda zai iya samun kariya mai kyau.Hanyar ita ce da farko da za a liƙa lullubi na ruwan sanyi na azurfa a saman Mo, sannan a sa magudanar ruwa mai zafi.Ƙwararren brazing na azurfa yana da aiki a cikin ƙananan zafin jiki, kuma yawan zafin jiki mai zafi zai iya kaiwa 1427 ℃.

Abubuwan TA ko Nb sun fi dacewa da brazed a ƙarƙashin injin, kuma matakin injin bai gaza 1.33 × 10-2Pa ba.Idan ana yin brazing a ƙarƙashin kariya ta iskar gas, ƙazantattun iskar gas kamar carbon monoxide, ammonia, nitrogen da carbon dioxide dole ne a cire su sosai.Lokacin da brazing ko juriya brazing a cikin iska, musamman brazing na brazing karfe da kuma dace juriya za a yi amfani da.Don hana TA ko Nb tuntuɓar oxygen a cikin zafin jiki mai girma, ana iya sanya Layer na ƙarfe na ƙarfe ko nickel a saman kuma za a iya aiwatar da jiyya mai dacewa.

Lokacin aikawa: Juni-13-2022