Brazing na bakin karfe

1. Rashin hankali

Matsala ta farko a cikin bakin karfe brazing shine cewa fim din oxide a saman yana da matukar tasiri ga jika da yada solder.Bakin karfe iri-iri na dauke da adadi mai yawa na Cr, wasu kuma suna dauke da Ni, Ti, Mn, Mo, Nb da sauran abubuwa, wadanda za su iya samar da nau'in oxide iri-iri ko ma hadadden oxides a saman.Daga cikin su, oxides Cr2O3 da TiO2 na Cr da Ti sun tsaya tsayin daka kuma suna da wahalar cirewa.Lokacin brazing a cikin iska, dole ne a yi amfani da motsi mai aiki don cire su;Lokacin brazing a cikin yanayi mai karewa, ana iya rage fim ɗin oxide kawai a cikin yanayi mai tsabta tare da ƙarancin raɓa da isasshen zafin jiki;A cikin injin brazing, ya zama dole a sami isasshen sarari da isasshen zafin jiki don samun sakamako mai kyau na brazing.

Wani matsala na bakin karfe brazing shine cewa zafin jiki na dumama yana da mummunar tasiri akan tsarin karfen tushe.The brazing dumama zafin jiki na austenitic bakin karfe ba zai zama sama da 1150 ℃, in ba haka ba hatsi zai yi girma da gaske;Idan bakin karfe austenitic ba ya ƙunshe da tsayayyen sinadari Ti ko Nb kuma yana da babban abun ciki na carbon, brazing a cikin yanayin zafin hankali (500 ~ 850 ℃) kuma za a guji.Don hana juriyar lalata daga raguwa saboda hazo na chromium carbide.Zaɓin zafin jiki na brazing don bakin karfe na martensitic ya fi tsauri.Daya shine a daidaita zafin brazing tare da zafin jiki na kashewa, don haɗa tsarin brazing tare da tsarin maganin zafi;Ɗayan kuma shine cewa zafin jiki na brazing ya kamata ya zama ƙasa da zafin jiki don hana ƙananan ƙarfe daga laushi lokacin brazing.Ƙa'idar zaɓin zafin jiki na brazing na hazo hardening bakin karfe iri ɗaya ne da na bakin ƙarfe na martensitic, wato, zazzabin brazing dole ne ya dace da tsarin kula da zafi don samun mafi kyawun kayan aikin injiniya.

Baya ga manyan matsalolin guda biyu da ke sama, akwai yanayi na fashewar damuwa lokacin da ake yin brazing austenitic bakin karfe, musamman lokacin yin brazing da karfen zinc filler na jan karfe.Don guje wa fashewar damuwa, aikin aikin za a sauke shi da damuwa kafin a yi brazing, kuma aikin aikin ya kasance mai zafi iri ɗaya yayin brazing.

2. Brazing abu

(1) Dangane da buƙatun amfani da kayan aikin ƙarfe na ƙarfe, ƙarfen ƙarfe na ƙarfe da aka saba amfani da shi don ƙera bakin karfe sun haɗa da Tin Lead brazing filler karfe, ƙarfe na ƙarfe na ƙarfe na ƙarfe, ƙarfe na ƙarfe na ƙarfe na ƙarfe, ƙarfe na ƙarfe na ƙarfe na ƙarfe, manganese tushen brazing filler karfe, tushen nickel. brazing filler karfe da darajan karfe brazing filler karfe.

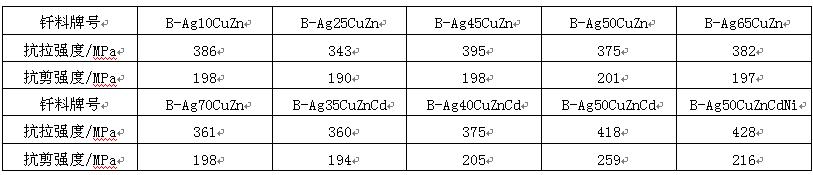

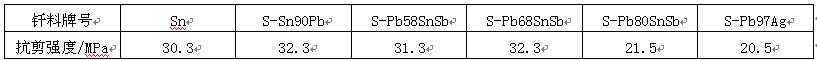

Ana amfani da siyar da gubar dalma galibi don siyar da bakin karfe, kuma ya dace da samun babban abun ciki na kwano.Mafi girman abun ciki na gwangwani na solder, mafi kyawun jiyyarsa akan bakin karfe.Ƙarfin ƙarfi na 1Cr18Ni9Ti bakin karfe haɗin gwiwa tare da masu siyar da gubar kwano da yawa an jera su a cikin Tebura 3. Saboda ƙarancin ƙarfin haɗin gwiwa, ana amfani da su kawai don sassan brazing tare da ƙaramin ƙarfi.

Tebur 3 ƙarfin ƙarfi na 1Cr18Ni9Ti bakin karfe haɗin gwiwa brazed tare da tin gubar solder

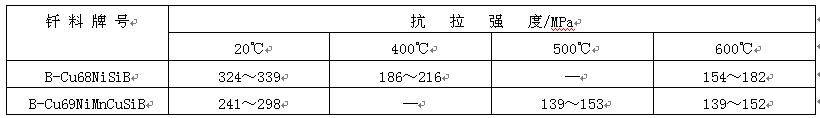

Ƙarfan filaye na tushen Azurfa sune mafi yawan ƙarfe da ake amfani da su don sarrafa bakin karfe.Daga cikin su, an fi amfani da ƙarfe na jan ƙarfe na zinc da azurfa tagulla zinc cadmium filler karafa saboda yawan zafin jiki na brazing yana da ɗan tasiri akan kaddarorin ƙarfe na tushe.Ƙarfin ICr18Ni9Ti bakin karfe gidajen abinci brazed tare da na kowa na kowa azurfa tushen solders an jera a cikin Table 4. The bakin karfe gidajen abinci brazed tare da azurfa tushen solders da wuya a yi amfani da sosai m kafofin watsa labarai, da kuma aiki zafin jiki na gidajen abinci kullum ba ya wuce 300 ℃ .Lokacin brazing bakin karfe ba tare da nickel ba, don hana lalata haɗin gwiwa a cikin yanayi mai ɗanɗano, za a yi amfani da ƙarfe mai cike da nickel, kamar b-ag50cuzncdni.Lokacin brazing martensitic bakin karfe, don hana taushi na tushe karfe, brazing filler karfe tare da brazing zafin jiki wanda bai wuce 650 ℃ za a yi amfani, kamar b-ag40cuzncd.Lokacin brazing bakin karfe a cikin yanayi mai kariya, domin a cire fim din oxide a saman, ana iya amfani da lithium mai dauke da brazing juzu'i, kamar b-ag92culi da b-ag72culi.Lokacin brazing bakin karfe a cikin injin, don yin filler karfe har yanzu yana da kyau wettability lokacin da ba ya ƙunshi abubuwa kamar Zn da CD masu sauƙin ƙafewa, ƙarfen filler na azurfa yana ɗauke da abubuwa kamar Mn, Ni da RD na iya zama. zaba.

Tebur 4 ƙarfi na ICr18Ni9Ti bakin karfe hadin gwiwa brazed tare da azurfa tushen filler karfe

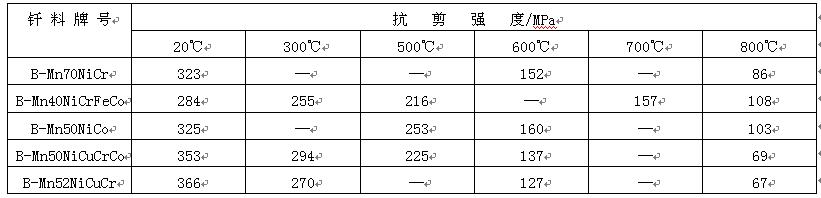

Karfe na brazing na ƙarfe da ake amfani da su don brazing karafa daban-daban galibi ana yin su ne tagulla, jan ƙarfe nickel da jan ƙarfe na manganese cobalt brazing filler karafa.Tsaftataccen ƙarfe mai cike da brazing na tagulla ana amfani da shi ne musamman don brazing ƙarƙashin kariyar gas ko vacuum.The aiki zafin jiki na bakin karfe hadin gwiwa ne ba fiye da 400 ℃, amma hadin gwiwa yana da matalauta hadawan abu da iskar shaka juriya.Karfe nickel brazing filler ana amfani da shi ne musamman don murƙushe wuta da brazing induction.Ƙarfin haɗin gwiwar 1Cr18Ni9Ti bakin karfe da aka yi wa brazed an nuna shi a cikin Tebur 5. Ana iya ganin cewa haɗin gwiwa yana da ƙarfi iri ɗaya kamar ƙarfe mai tushe, kuma zafin aiki yana da girma.Cu Mn co brazing filler karfe ana amfani dashi galibi don sarrafa bakin karfe na martensitic a cikin yanayin kariya.Ƙarfin haɗin gwiwa da zafin aiki sun yi kama da waɗanda aka yi wa brazed da ƙarfe na tushen gwal.Misali, 1Cr13 bakin karfe hadin gwiwa brazed tare da b-cu58mnco solder yana da irin wannan aiki kamar guda bakin karfe hadin gwiwa brazed tare da b-au82ni solder (duba Table 6), amma samar da aka rage sosai.

Tebur 5 ƙarfin ƙarfi na 1Cr18Ni9Ti bakin karfe haɗin gwiwa brazed tare da babban zafin jiki na ƙarfe tushe filler karfe

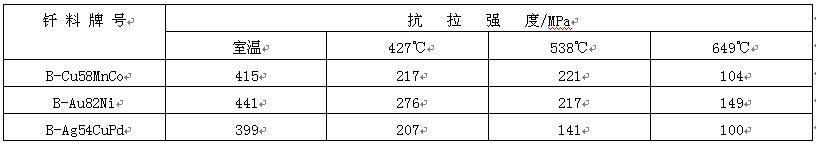

Tebur 6 ƙarfin ƙarfi na 1Cr13 bakin karfe brazed haɗin gwiwa

Manganese tushen brazing karafa ana amfani da yafi amfani da iskar gas kariya brazing, kuma ana bukatar tsarkin gas ya zama babba.Don guje wa haɓakar hatsin ƙarfe na tushe, ya kamata a zaɓi ƙarfe mai cike da brazing daidai tare da zazzabi mai ƙasa da 1150 ℃.Za a iya samun sakamako mai gamsarwa na brazing don gidajen abinci na bakin karfe da aka yi tare da manganese tushen solder, kamar yadda aka nuna a cikin Tebur 7. Zazzabi mai aiki na haɗin gwiwa zai iya kaiwa 600 ℃.

Tebur 7 ƙarfin ƙarfi na lcr18ni9fi bakin karfe haɗin gwiwa brazed da manganese tushen filler karfe

Lokacin da bakin karfe yana brazed tare da nickel tushe filler karfe, haɗin gwiwa yana da kyakkyawan aikin zafin jiki.Ana amfani da wannan ƙarfe na filler gabaɗaya don garkuwar gas ɗin brazing ko vacuum brazing.Don shawo kan matsalar cewa an samar da ƙarin mahadi masu gatsewa a cikin haɗin gwiwa da aka yi da brazed yayin haɓakar haɗin gwiwa, wanda ke rage ƙarfi da filastik na haɗin gwiwa sosai, ya kamata a rage girman tazarar haɗin gwiwa don tabbatar da cewa abubuwan cikin sauƙi don samar da gaggautuwa lokaci a cikin haɗin gwiwa. solder suna cikakke ya bazu cikin ƙarfen tushe.Don hana abin da ya faru na ci gaban hatsin ƙarfe na tushe saboda dogon lokacin riƙewa a zafin jiki na brazing, ana iya ɗaukar matakan aiwatar da ɗaukar ɗan gajeren lokaci da jiyya a cikin ƙananan zafin jiki (idan aka kwatanta da zafin jiki na brazing) bayan walda.

Ƙarfe mai cike da ƙarfe na ƙarfe da aka yi amfani da shi don brazing bakin karfe galibi sun haɗa da karafa na tushen gwal da palladium mai ɗauke da karafa mai filler, waɗanda mafi yawan su ne b-au82ni, b-ag54cupd da b-au82ni, waɗanda ke da ingantaccen wettability.The brazed bakin karfe hadin gwiwa yana da high high zafin jiki ƙarfi da hadawan abu da iskar shaka juriya, da kuma matsakaicin aiki zafin jiki iya isa 800 ℃.B-ag54cupd yana da halaye iri ɗaya zuwa b-au82ni kuma farashinsa yayi ƙasa, don haka yana ƙoƙarin maye gurbin b-au82ni.

(2) Fuskar bakin karfe a cikin juyi da yanayin tanderun ya ƙunshi oxides kamar Cr2O3 da TiO2, waɗanda za a iya cire su kawai ta amfani da juzu'i tare da aiki mai ƙarfi.Lokacin da bakin karfe yana brazed tare da tin gubar solder, dacewar juyi shine maganin ruwa na phosphoric acid ko maganin zinc oxide hydrochloric acid.Lokacin aiki na maganin ruwa na phosphoric acid gajere ne, don haka dole ne a ɗauki hanyar brazing na saurin dumama.Fb102, fb103 ko fb104 fluxes za a iya amfani da su don brazing bakin karfe tare da azurfa tushen filler karafa.Lokacin brazing bakin karfe tare da tushen jan karfe mai cike da jan karfe, fb105 ana amfani da juzu'i saboda tsananin zafin brazing.

Lokacin brazing bakin karfe a cikin tanderun, vacuum yanayi ko kariya yanayi kamar hydrogen, argon da bazuwar ammonia yawanci amfani.A lokacin injin brazing, matsa lamba zai zama ƙasa da 10-2Pa.Lokacin brazing a cikin yanayi mai karewa, wurin raɓa na iskar gas ɗin ba zai zama sama da -40 ℃ Idan tsarkin iskar gas bai isa ba ko kuma zafin zafin brazing bai yi girma ba, ƙaramin adadin gas brazing flux, kamar boron trifluoride, zai iya. a kara zuwa yanayi.

2. Fasahar Brazing

Bakin karfe dole ne a tsaftace shi sosai kafin brazing don cire kowane maiko da fim ɗin mai.Zai fi kyau a yi braze nan da nan bayan tsaftacewa.

Bakin ƙarfe brazing na iya ɗaukar harshen wuta, shigarwa da tanderu matsakaicin hanyoyin dumama.Tanderun don brazing a cikin tanderun dole ne ya sami tsarin kula da zafin jiki mai kyau (ana buƙatar karkatar da zafin jiki don zama ± 6 ℃) kuma ana iya sanyaya cikin sauri.Lokacin da hydrogen ake amfani da shi azaman garkuwar gas don brazing, abubuwan da ake buƙata don hydrogen sun dogara ne akan zafin brazing da abun da ke cikin ƙarfe na tushe, wato, ƙananan zafin jiki na brazing, ƙarin ƙarfen tushe yana ƙunshe da stabilizer, kuma rage raɓa Ana buƙatar batu na hydrogen.Alal misali, don martensitic bakin karfe irin su 1Cr13 da cr17ni2t, lokacin da brazing a 1000 ℃, da raɓa batu na hydrogen ake bukata ya zama ƙasa da -40 ℃;Domin 18-8 chromium nickel bakin karfe ba tare da stabilizer, da raɓa batu na hydrogen zai zama ƙasa da 25 ℃ a lokacin brazing a 1150 ℃;Duk da haka, don 1Cr18Ni9Ti bakin karfe dauke da titanium stabilizer, hydrogen dew batu dole ne kasa da -40 ℃ lokacin brazing a 1150 ℃.Lokacin brazing tare da kariyar argon, ana buƙatar tsarkin argon ya zama mafi girma.Idan jan karfe ko nickel aka yi wa saman bakin karfe, ana iya rage abin da ake bukata don tsabtar iskar kariya.Domin tabbatar da cire fim din oxide a saman bakin karfe, ana iya ƙara yawan iskar gas na BF3, kuma ana iya amfani da lithium ko boron mai ɗauke da siyar da kai.Lokacin vacuum brazing bakin karfe, buƙatun digiri na injin ya dogara da zafin brazing.Tare da haɓakar zafin jiki na brazing, za'a iya rage buƙatun da ake buƙata.

Babban tsari na bakin karfe bayan brazing shine tsaftace saura ruwa da mai hana kwarara ruwa, da aiwatar da maganin zafi bayan brazing idan ya cancanta.Dangane da juzu'i da hanyar brazing da aka yi amfani da su, za a iya wanke saura jujjuya da ruwa, a tsaftace ta inji ko kuma a tsaftace ta hanyar sinadarai.Idan an yi amfani da abrasive don tsaftace ragowar ruwa ko fim ɗin oxide a cikin wuri mai zafi kusa da haɗin gwiwa, za a yi amfani da yashi ko wasu abubuwan da ba na ƙarfe ba.Sassan da aka yi da bakin karfe na martensitic da hazo hardening bakin karfe suna buƙatar magani mai zafi bisa ga buƙatun musamman na kayan bayan brazing.Abubuwan haɗin gwiwar bakin karfe da aka yi tare da Ni Cr B da Ni Cr Si filler karafa galibi ana bi da su tare da yaduwar zafin zafin jiki bayan brazing don rage buƙatun don tazarar brazing da haɓaka microstructure da kaddarorin haɗin gwiwa.

Lokacin aikawa: Juni-13-2022