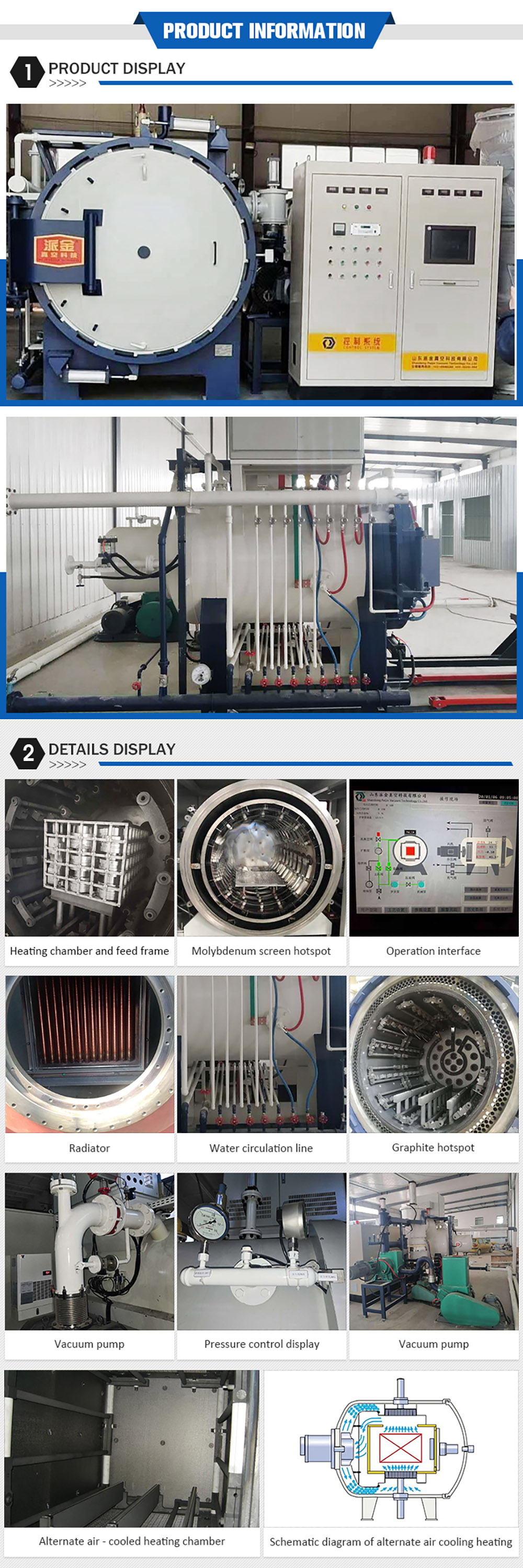

vacuum gas quenching makera A tsaye tare da ɗaki ɗaya

Me ke kashe iskar gas

Vacuum gas quenching shine tsarin dumama kayan aikin a ƙarƙashin injin, sannan sanyaya shi da sauri a cikin iskar gas mai sanyaya tare da babban matsi da ƙimar kwarara mai girma, don haɓaka taurin saman aikin.

Idan aka kwatanta da talakawa gas quenching, man quenching da gishiri wanka quenching, injin high-matsa lamba gas quenching yana da fili abũbuwan amfãni: mai kyau surface quality, babu hadawan abu da iskar shaka kuma babu carburization; Kyakkyawan quenching uniformity da kananan workpiece nakasawa; Kyakkyawan iko na ƙarfin kashewa da ƙimar sanyaya mai sarrafawa; Babban yawan aiki, ceton aikin tsaftacewa bayan quenching; Babu gurbatar muhalli.

Akwai abubuwa da yawa da suka dace da vacuum high-matsi gas quenching, yafi ciki har da: high-gudun karfe (kamar yankan kayan aiki, karfe molds, mutu, ma'auni, bearings ga jet injuna), kayan aiki karfe (agogo, kayan aiki, presses), mutu karfe, bearing karfe, da dai sauransu.

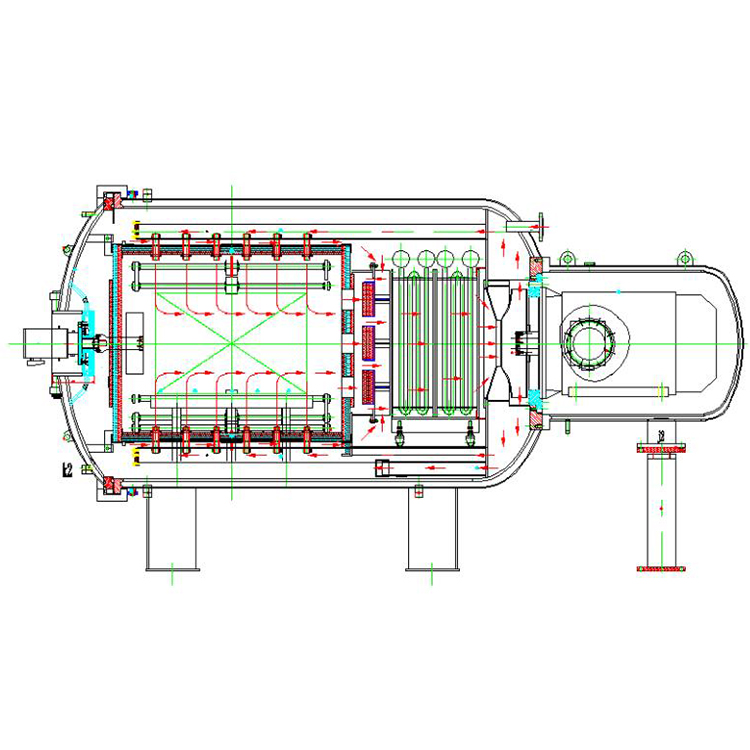

Paijin Vacuum gas quenching makera shine injin injin tanderu wanda ya kunshi jikin tanderun, dakin dumama, fan mai zafi, tsarin injin, tsarin cika gas, tsarin matsa lamba, tsarin sarrafa wutar lantarki, tsarin sanyaya ruwa, tsarin kashe gas, tsarin pneumatic, injin tanderu mai sarrafa wutar lantarki da tsarin samar da wutar lantarki.

Aikace-aikace

Paijin Vacuum gas quenching makeradace da quenching magani na kayan kamar mutu karfe, high-gudun karfe, bakin karfe, da dai sauransu; maganin maganin kayan aiki irin su bakin karfe, titanium da titanium gami; annealing jiyya da tempering jiyya na daban-daban Magnetic kayan; kuma za'a iya amfani dashi don ɓacin rai da vacuum sintering.

Halaye

1. Babban saurin sanyaya:ta amfani da babban inganci murabba'in zafi Exchanger, ta sanyaya kudi yana ƙaruwa da 80%.

2. Kyakkyawan daidaitawa mai sanyaya:An saita nozzles na iska a ko'ina kuma an saita su a ko'ina a kewayen ɗakin dumama.

3.Mai Girman Makamashi:Nozzles na iska za su rufe ta atomatik a tsarin dumama, yana sa farashin makamashi ya ragu da kashi 40%.

4. Ingantacciyar daidaiton zafin jiki:Abubuwan dumama nata sun daidaita daidai gwargwado a kewayen dakin dumama.

5. Ya dace da yanayin tsari daban-daban:Wurin dumama ɗakinta na rufi ana yin shi ta hanyar haɗaɗɗen rufin rufin rufin ƙarfe ko allon rufe fuska, wanda ya dace da yanayi daban-daban.

6. Smart da sauki don aiwatar da shirye-shiryen, barga da abin dogara aikin injiniya, ta atomatik, Semi-atomatik ko mai ban tsoro da hannu da nuna kuskure.

7. Mitar jujjuyawar jujjuyawar iskar gas mai kashe fan, dumama iska ta zaɓi, zaɓin 9 maki zazzabi binciken, jujjuyawar matsa lamba da quenching isothermal.

8. Tare da dukan AI kula da tsarin da wani karin manual aiki tsarin.

Daidaitaccen ƙirar ƙirar ƙira da sigogi

| Daidaitaccen ƙirar ƙirar ƙira da sigogi | |||||

| Samfura | Saukewa: PJ-Q557 | Saukewa: PJ-Q669 | Saukewa: PJ-Q7711 | Saukewa: PJ-Q8812 | Saukewa: PJ-Q9916 |

| Ingantacciyar Yankin Zafi LWH (mm) | 500*500 * 700 | 600*600* 900 | 700*700* 1100 | 800*800* 1200 | 900*900*1600 |

| Nauyin Load (kg) | 300 | 500 | 800 | 1200 | 2000 |

| Matsakaicin Zazzabi(℃) | 1350 | ||||

| Daidaitaccen sarrafa zafin jiki (℃) | ±1 | ||||

| Daidaita yanayin zafin wuta (℃) | ±5 | ||||

| Matsakaicin Degree Vacuum (Pa) | 4.0 * E-1 | ||||

| Matsakaicin haɓaka (Pa/H) | ≤ 0.5 | ||||

| Matsin iskar gas (Bar) | 10 | ||||

| Tsarin wuta | A kwance, ɗaki ɗaya | ||||

| Hanyar buɗe kofar murhu | Nau'in hinge | ||||

| Abubuwan dumama | Abubuwan dumama graphit | ||||

| Zauren dumama | Tsarin tsari na Graphit mai wuyar ji da taushin ji | ||||

| Nau'in kwararar iskar gas | A tsaye kwarara kwarara | ||||

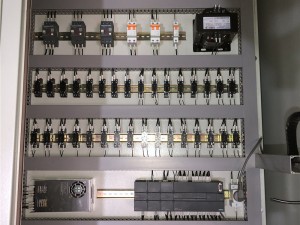

| PLC & Electric abubuwa | Siemens | ||||

| Mai sarrafa zafin jiki | EUROTHERM | ||||

| Vacuum famfo | Injin famfo da tushen famfo | ||||

| Keɓaɓɓen jeri na zaɓi | |||||

| Matsakaicin zafin jiki | 600-2800 ℃ | ||||

| Matsakaicin digiri | 6.7 * E-3 Pa | ||||

| Gas quenching matsa lamba | 6-20 Bar | ||||

| Tsarin wuta | A kwance, tsaye, ɗaki ɗaya ko ɗakuna da yawa | ||||

| Hanyar bude kofa | Nau'in hinge, Nau'in ɗagawa, Nau'in Flat | ||||

| Abubuwan dumama | Abubuwan dumama Graphit, Mo abubuwan dumama | ||||

| Zauren dumama | Haɗe-haɗe Graphite ji, Duk karfe nuna allo | ||||

| Nau'in kwararar iskar gas | Matsakaicin madaidaicin kwararar iskar gas; Matsakaicin canjin iskar gas | ||||

| Vacuum famfo | Injin famfo da famfo tushen; Makanikai, Tushen da famfunan yaduwa | ||||

| PLC & Electric abubuwa | Siemens, Omron, Mitsubishi, Siemens | ||||

| Mai sarrafa zafin jiki | EUROTHERM;SHIMADEN | ||||

Kula da inganci

Ingancin shine ruhun samfuran, shine maɓalli mai mahimmanci yanke shawarar masana'anta's future.Paijin dauki inganci a matsayin mafi fifiko al'amurran da suka shafi a cikin aikin yau da kullum.Don tabbatar da ingancin kayayyakin mu, mun biya sosai da hankali a kan 3 al'amurran.

1.Mafi mahimmanci: Mutum. Mutum shine mafi mahimmancin batu a kowane aiki. Muna da cikakken kwasa-kwasan horarwa ga kowane sabon ma'aikaci, kuma muna da tsarin tantance kowane ma'aikaci zuwa matakin (ƙanami, tsakiya, babba), ma'aikata daban-daban ana ɗaukar su ayyuka daban-daban tare da albashi daban-daban. A cikin wannan rating tsarin, shi's ba kawai da basira, amma kuma kudi a alhakin da kuskure kudi, zartarwa ikon da dai sauransu Ta wannan hanya, ma'aikata a cikin factory ne shirye su yi mafi kyau a cikin aikinsa. Kuma tsananin bi ingancin management dokokin.

2. Mafi kyawun kayan da aka gyara: Muna siyan mafi kyawun kayan a kasuwa, mun san cewa adana dala 1 a cikin kayan zai kashe dala 1000 a ƙarshe. The key sassa kamar lantarki aka gyara da kuma famfo ne duk iri kayayyakin kamar Siemens, Omron, Eurotherm, Schneider da dai sauransu Ga sauran sassa sanya a kasar Sin, za mu zabi mafi kyau factory a masana'antu da kuma sanya hannu samfurin ingancin guranntee kwangila tare da su, don tabbatar da kowane bangaren kowane sassa da muke amfani da su a cikin tanderu ne mafi ingancin kayayyakin.

3. Tsananin Ingancin Inganci: Muna da wuraren bincike masu inganci guda 8 a cikin hanyoyin samar da tanderu, jarrabawa a cikin kowane wurin duba ma'aikata 2 ne ke ɗaukar nauyi kuma manajan masana'anta 1 ne ke da alhakinsa. A cikin waɗannan wuraren bincike, kayan aiki da abubuwan haɗin gwiwa, da kowane ɓangaren tanderun ana duba su sau biyu don tabbatar da ingancinsa. A ƙarshe, kafin tanderu ya bar masana'anta, yakamata a bincika ta ƙarshe tare da gwaje-gwajen maganin zafi.